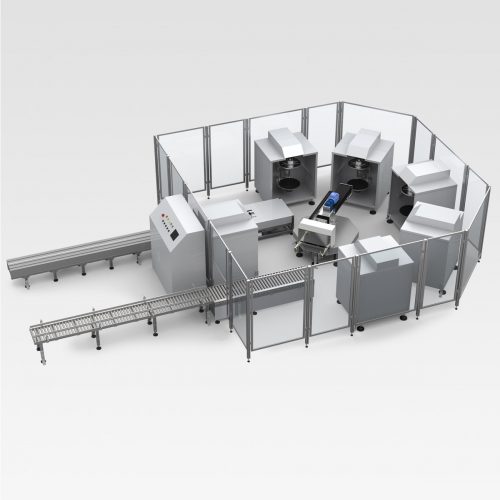

Unlock your productivity potential with the MODULA range of automated dispensers. With unrivaled flexibility and performance levels, MODULA can be tailored to meet your exact space requirements and productivity needs.

Experience the power of results-driven tinting solutions. Our high-efficiency, precision COROB MODULA dispensers are designed to meet extensive and varied demands, delivering reliable and flexible performance.

MODULA allows for just-in-time production with an unlimited range of colors and significant stock reduction.

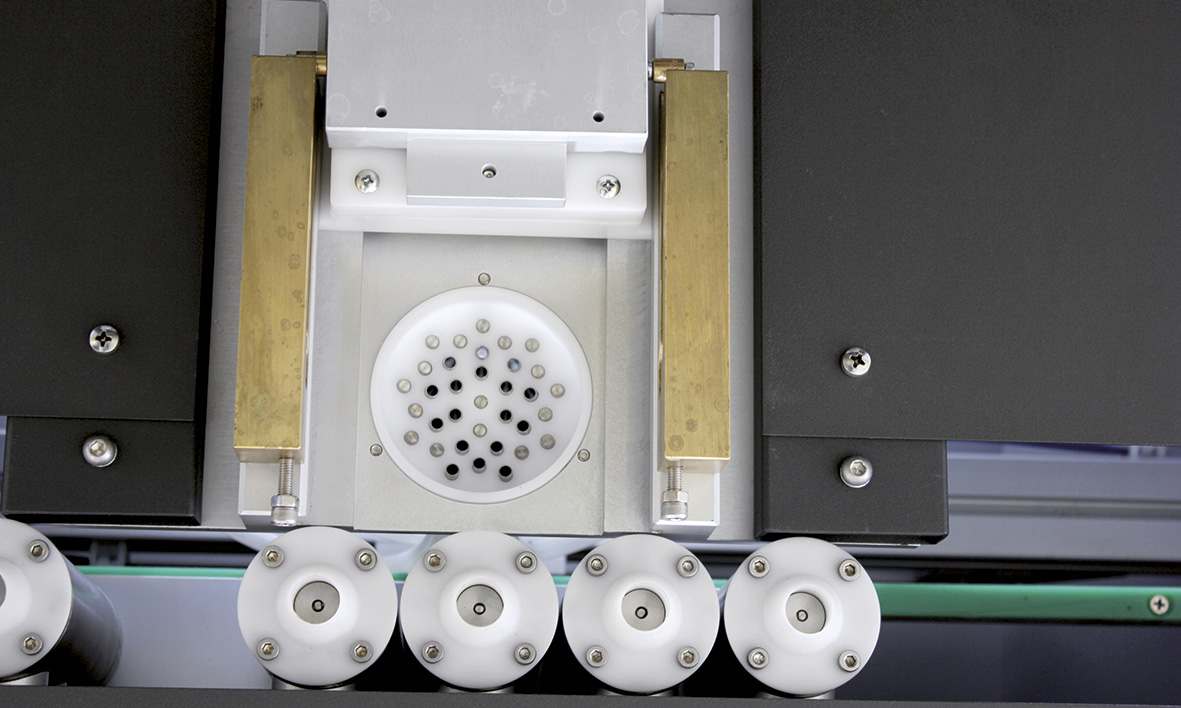

Choose from a wide selection of canister sizes and external tanks, and select from several pumping technologies to match your product characteristics.

The on-board equipment, consisting of up to 32 canisters and pumps, is designed to handle products that require lower flow rate performance. For products that require increased flow rate performance, up to 10 external tanks can be equipped with higher flow rate pumps.

Always at the forefront of innovation, we have developed a new patented high-speed dispensing system for our MODULA VG model. By adding the optional COROB VG-SIM module, you can boost your dispenser performance productivity by up to 30%.

With complete customizability to meet any budget or space requirement, our solutions are strategically positioned to shorten delivery times and reduce inventory needs, maximizing profitability.