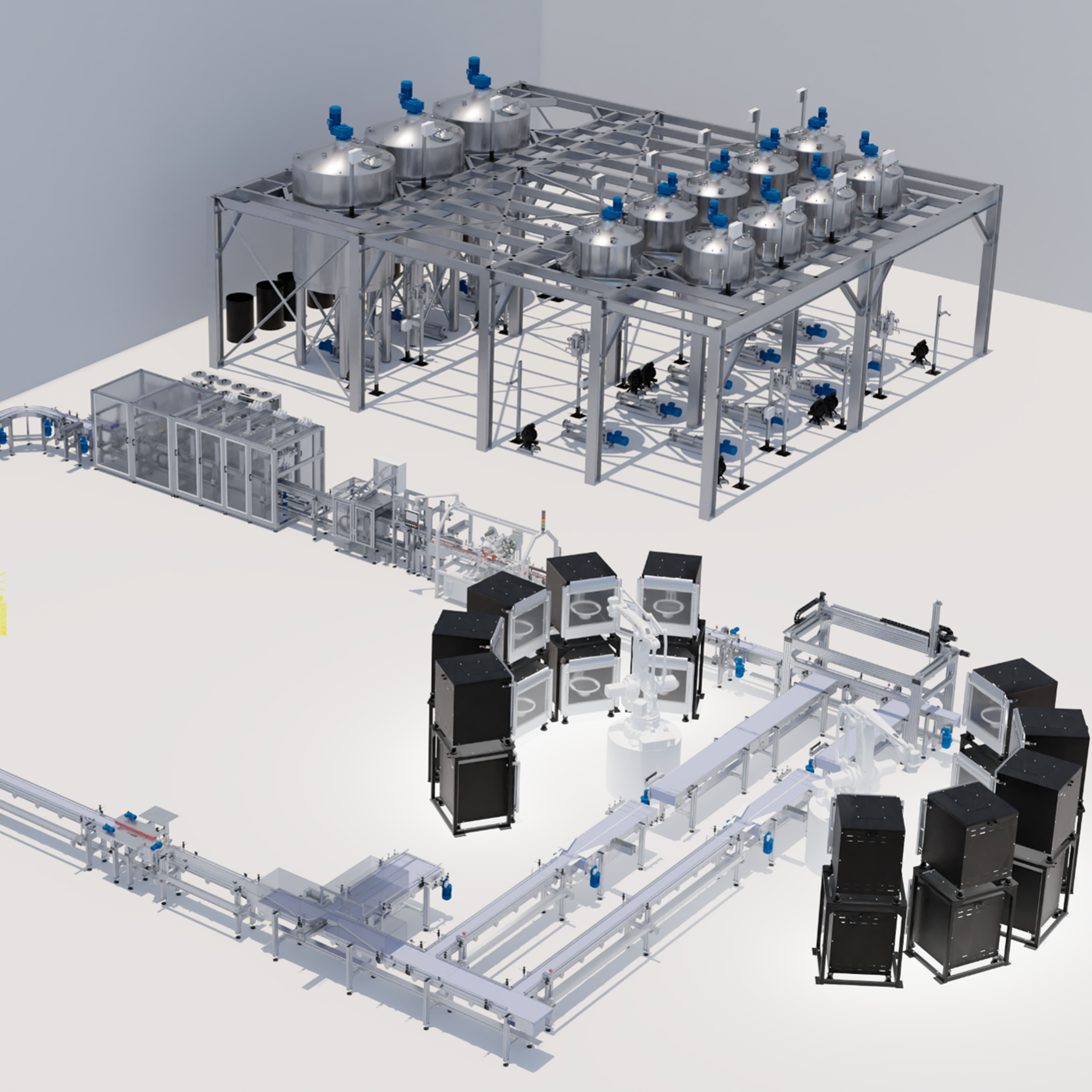

The COROB MS-LG Mixing Station is the perfect productivity enhancement for depots, warehouses, or large contractor retail locations, providing optimized performance while managing operating costs.

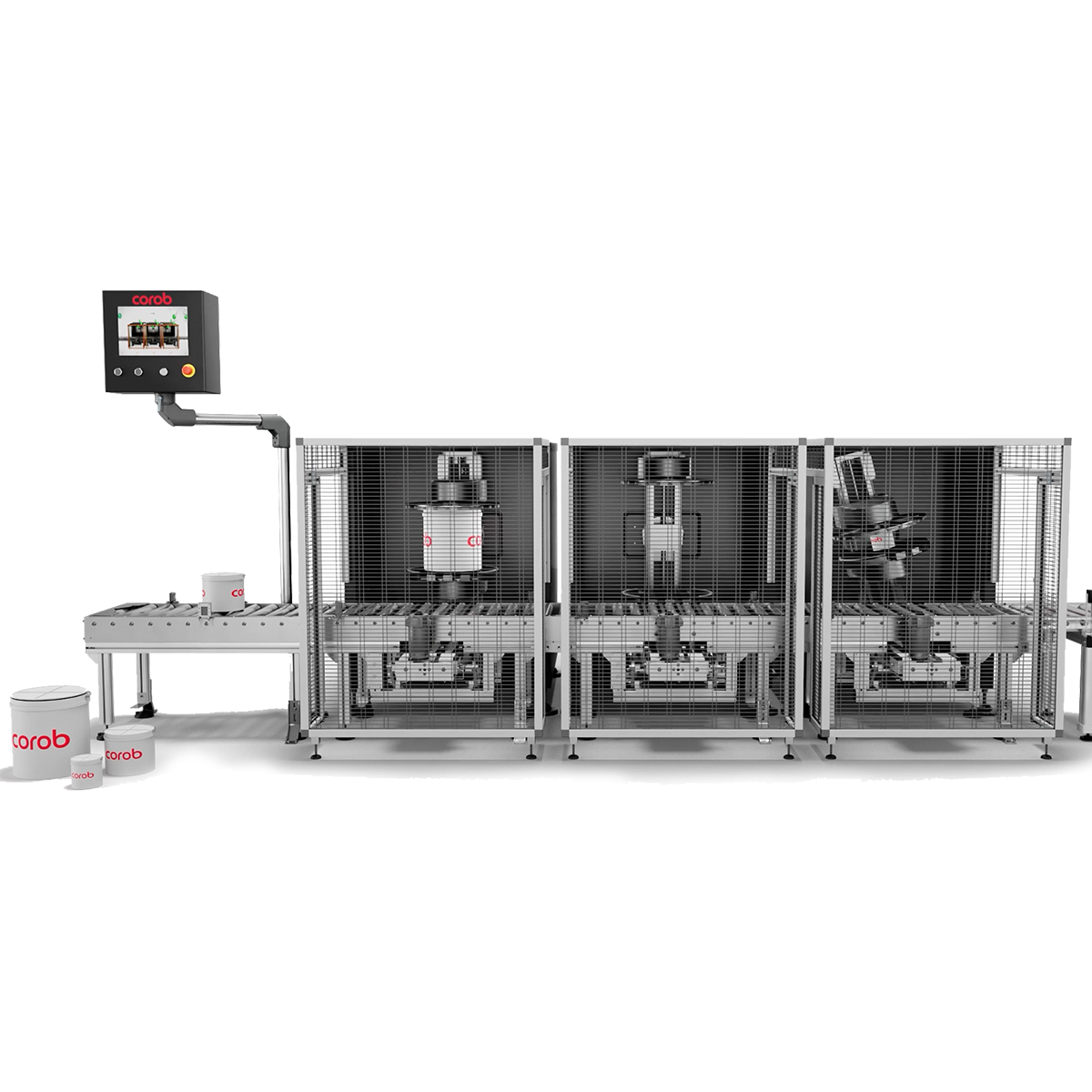

After the tinting process is completed, the MS-LG‘s automated conveyor system precisely loads and unloads paint cans of any size or shape into the powerful gyroscopic mixers. The optimized timing and the synchronized mixing cycle of the gyroscopic mixers provides a constant output of mixed paint pails in record time.

Operators or associates are relieved of the task of moving heavy paint cans, and the ergonomic layout of the conveyor system reduces fatigue and ensures a safe working environment.

The MS-LG comes with two gyroscopic mixers for optimal price and performance, but can be customized with up to three mixers for even greater productivity. With the MS-LG Mixing Station, you can achieve maximum efficiency and convenience in your mixing operations.