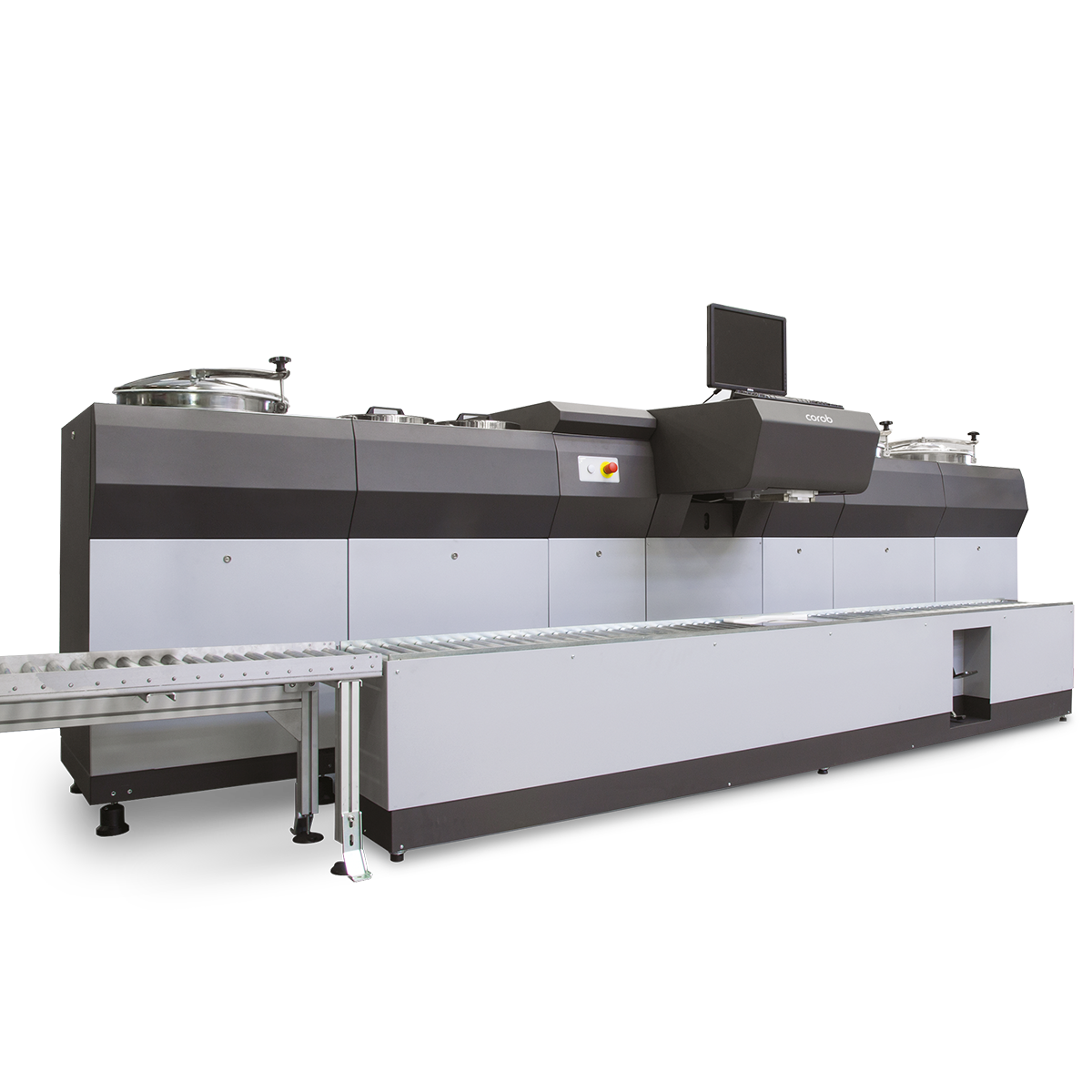

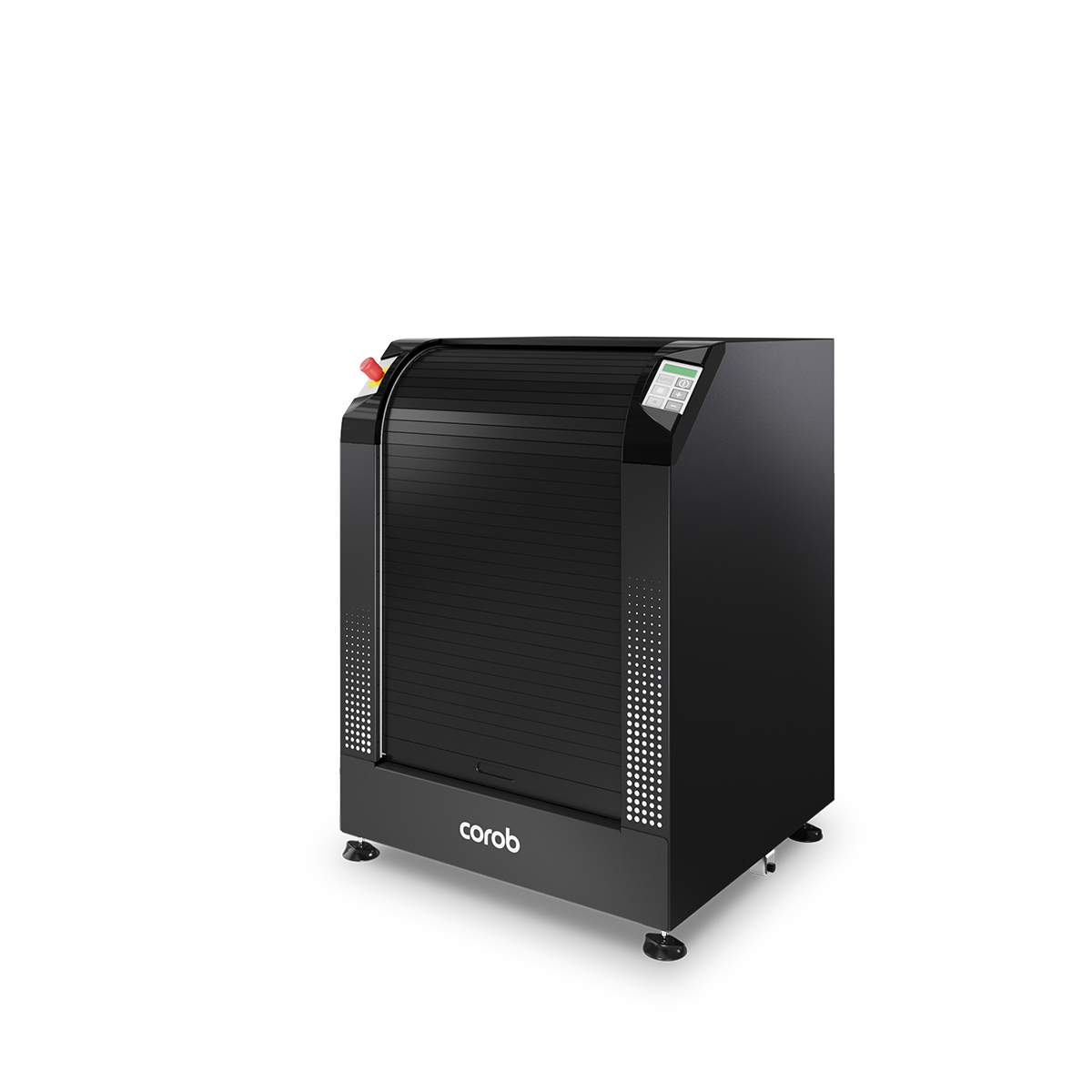

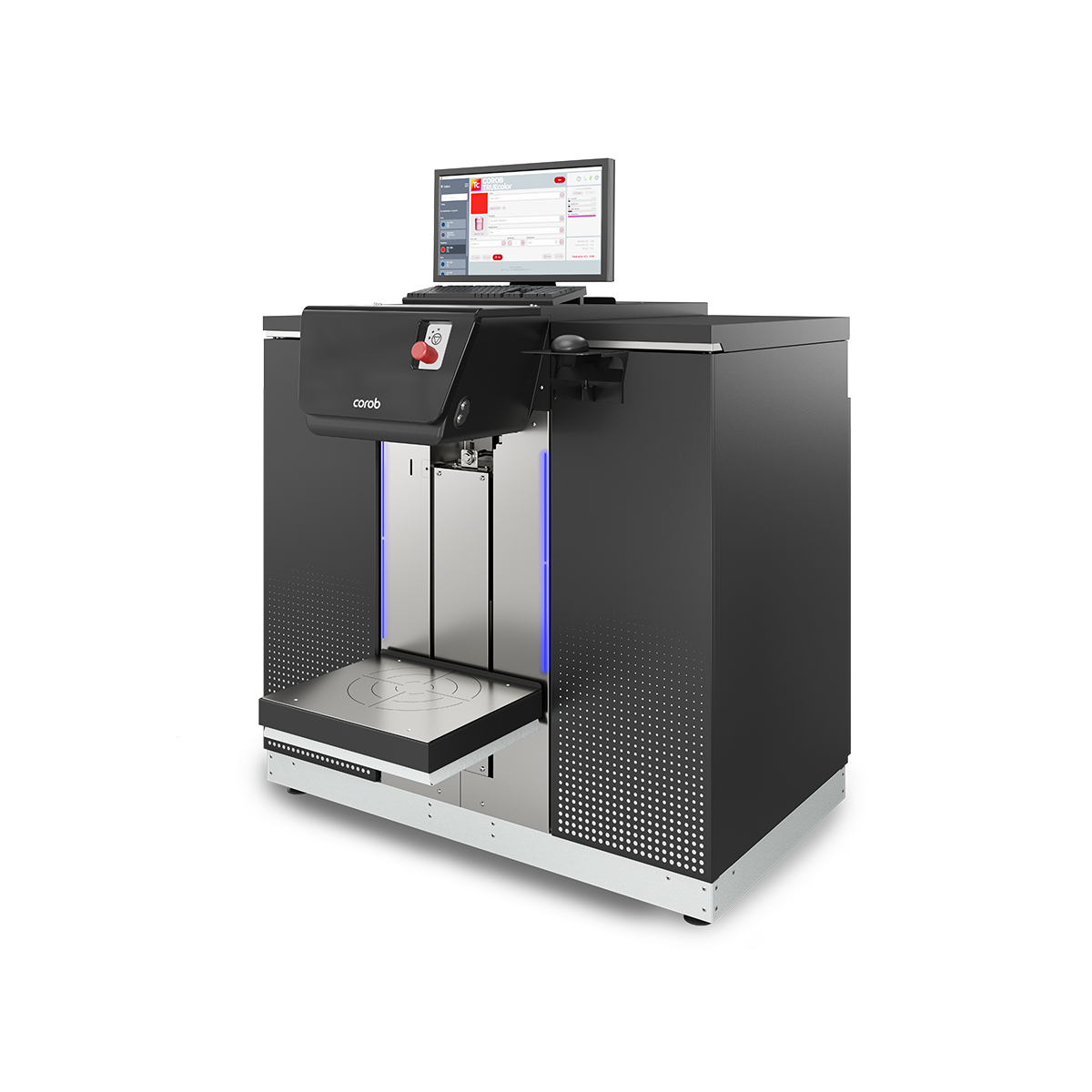

Unlock your productivity potential with the MODULA range of automated paint dispensers. With unrivaled flexibility and performance levels, MODULA can be tailored to meet your exact space requirements and productivity needs.

Experience the power of results-driven tinting solutions. Our high-efficiency, precision COROB MODULA dispensers are designed to meet extensive and varied demands, delivering reliable and flexible performance.

MODULA enables just-in-time production with an unlimited range of colors and significant stock reduction.

Choose from a wide selection of canister sizes and external tanks, and select from several pumping technologies to match your product characteristics.

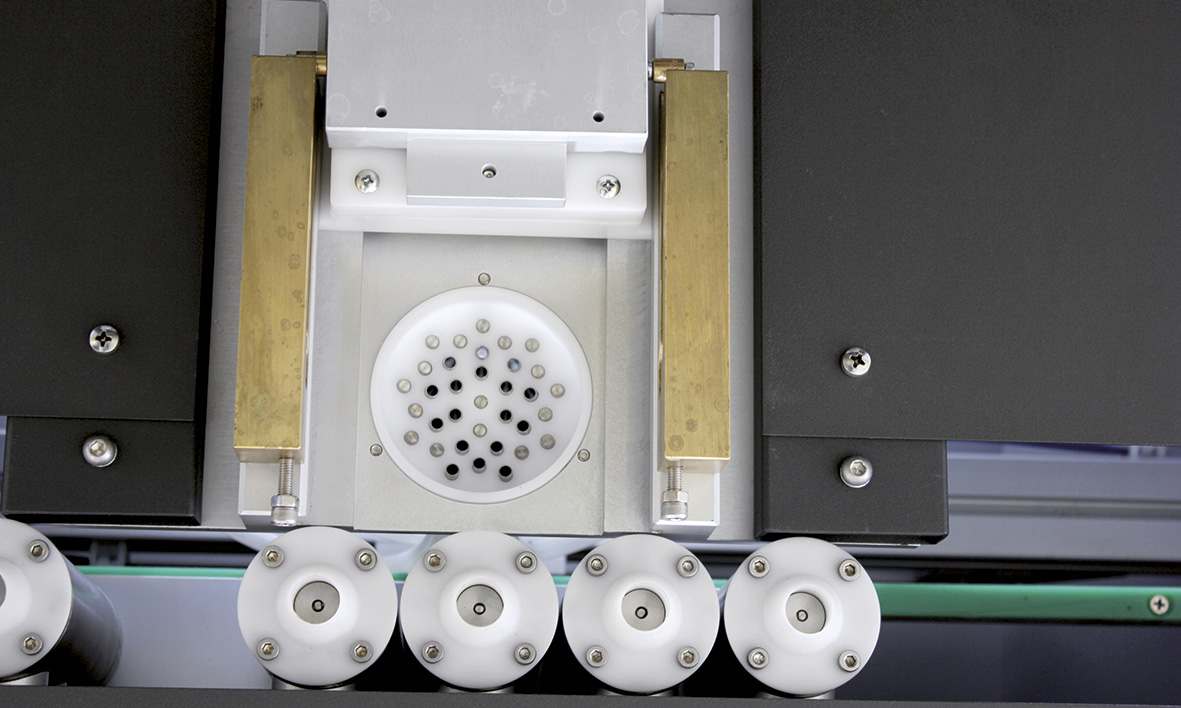

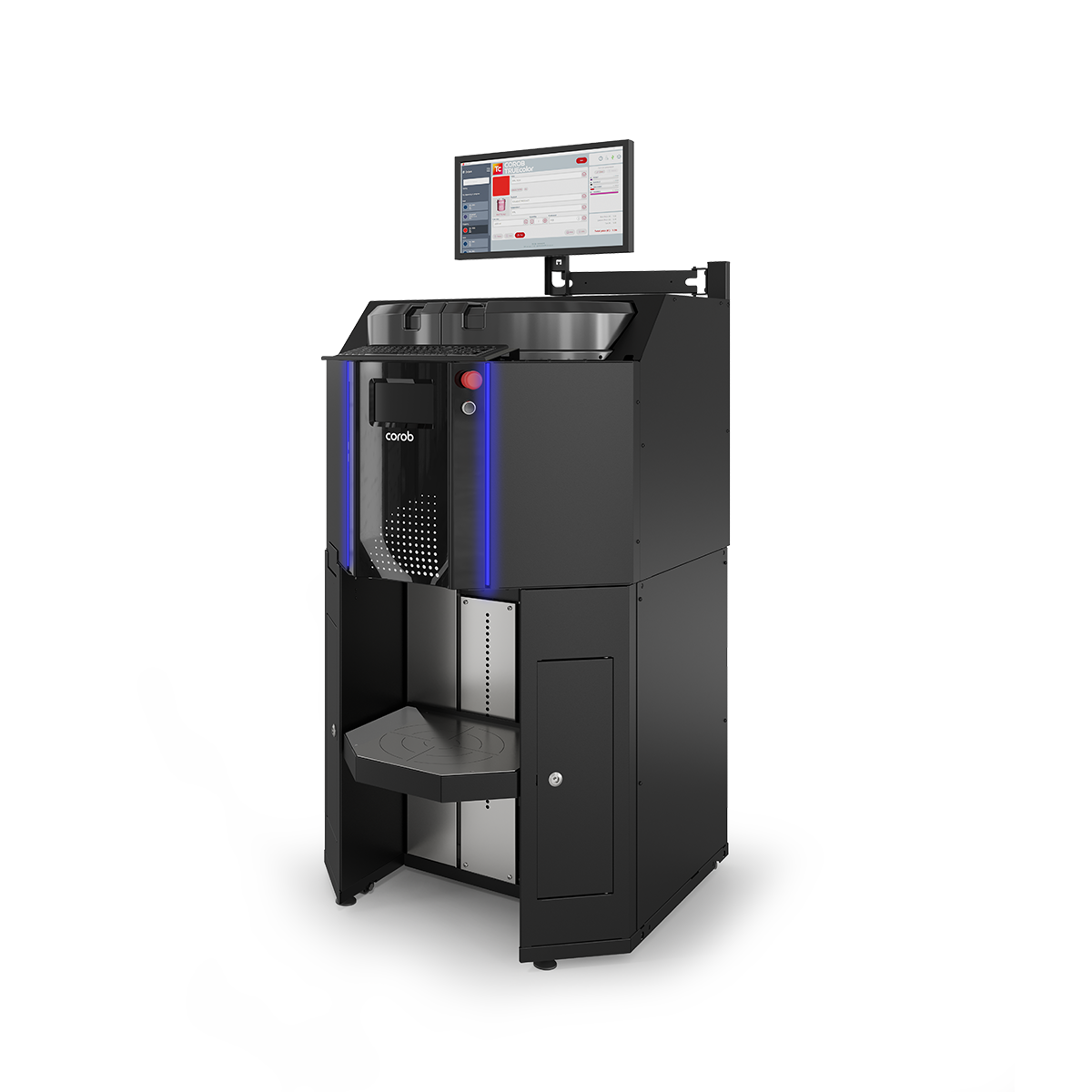

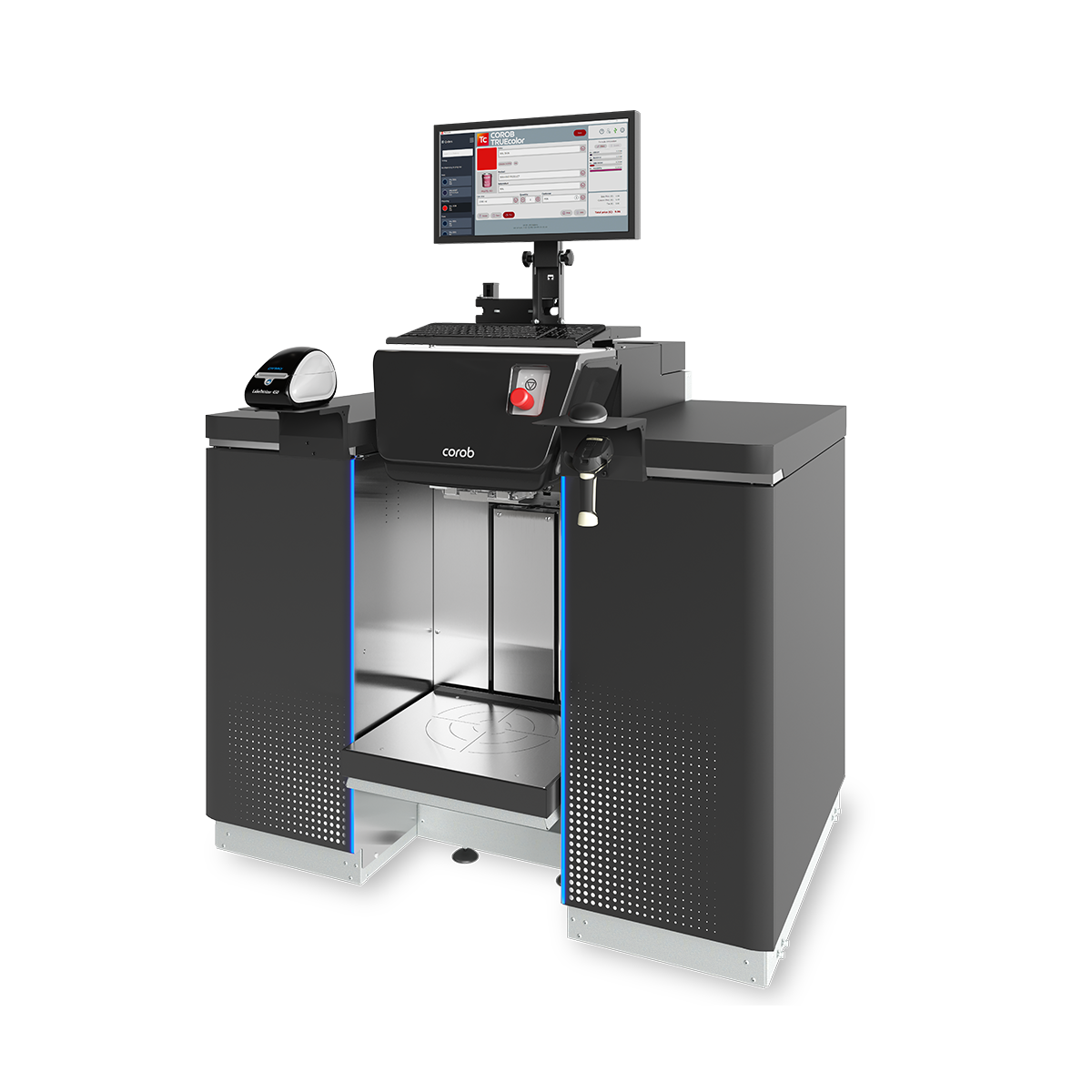

The on-board equipment, consisting of up to 32 canisters and pumps, is designed to handle products requiring lower flow rate performance. For higher flow rate needs, up to 10 external tanks can be equipped with high-capacity pumps.

Always at the forefront of innovation, we have developed a patented high-speed dispensing system for the MODULA VG model. By adding the optional COROB VG-SIM module, dispenser performance productivity can increase by up to 30%.

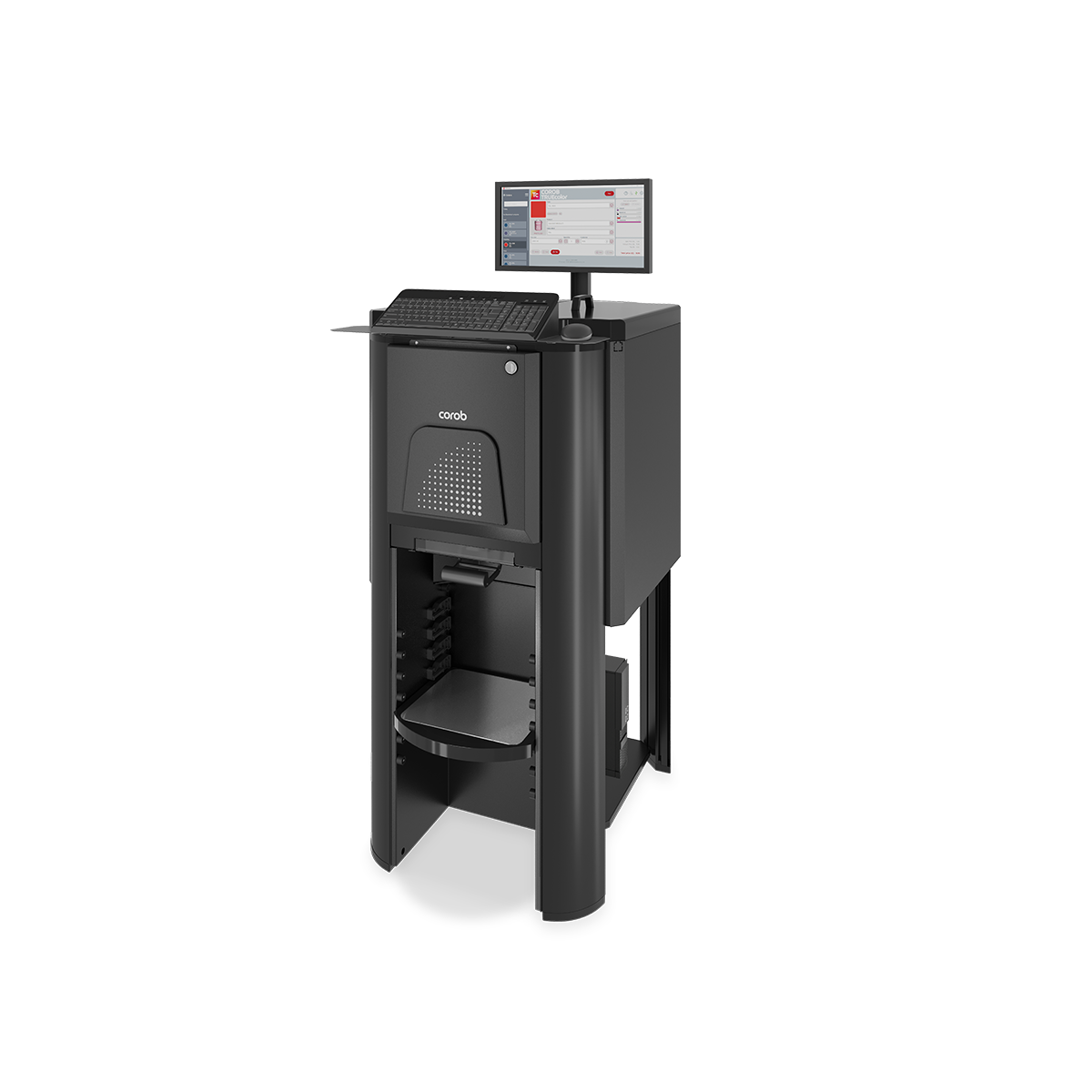

With complete customizability to meet any budget or space requirement, our solutions are strategically positioned to shorten delivery times and reduce inventory needs, maximizing profitability

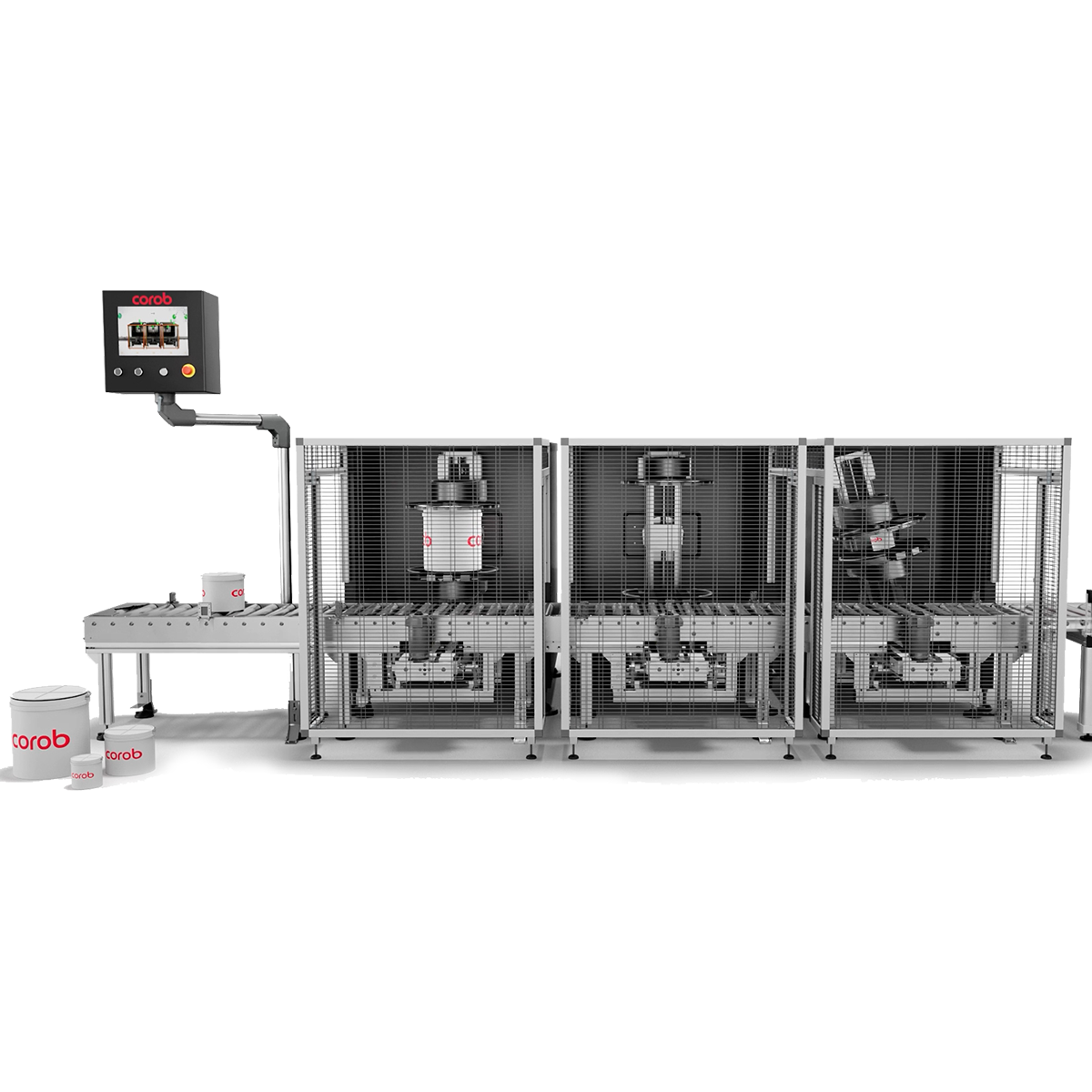

In-can production

The In-Can production system allows you to create a virtually unlimited number of tinted products while saving costs and minimizing production time.

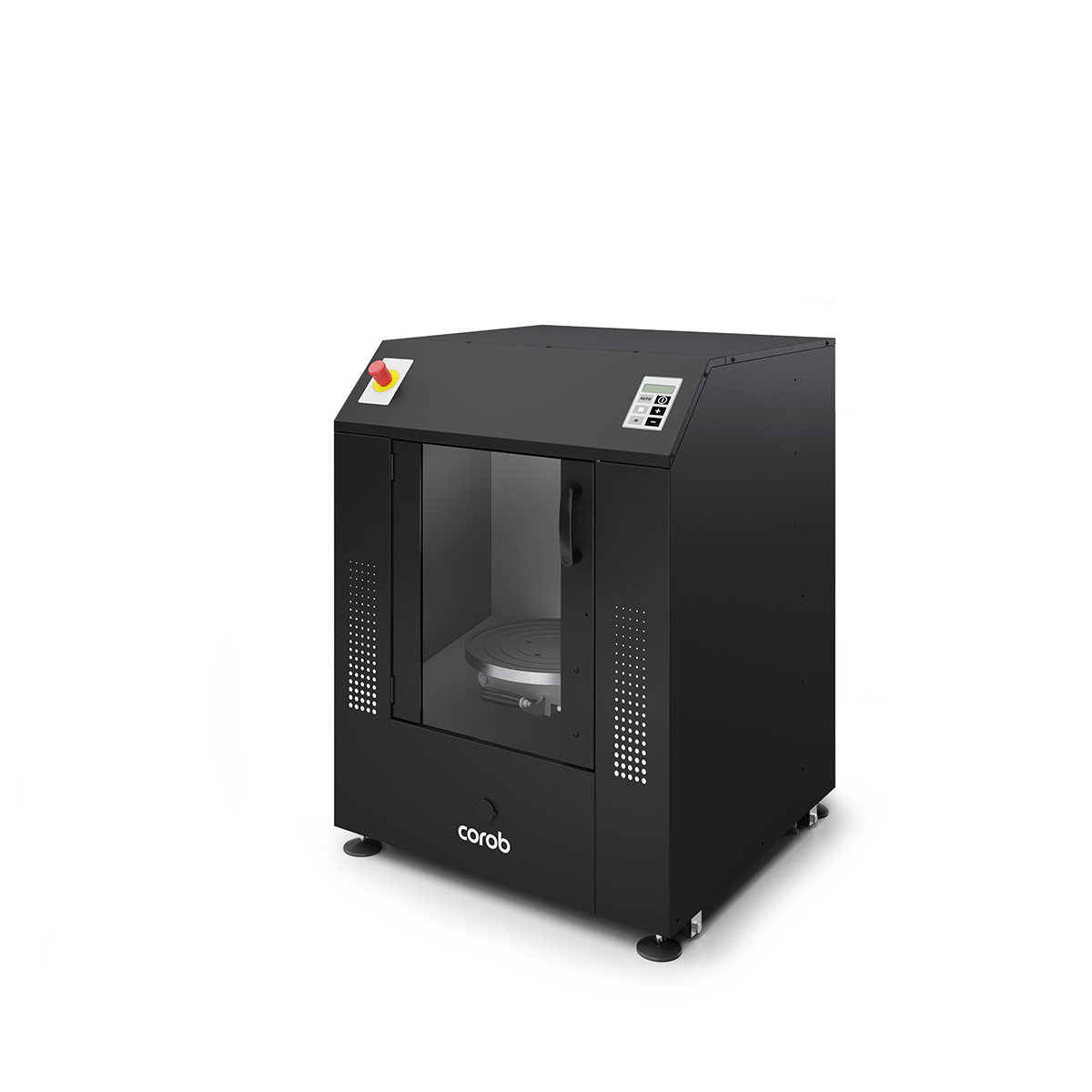

The Volu-gravimetric model (VG) combines the accuracy and speed of volumetric dispensing with gravimetric capabilities. This solution provides maximum flexibility and productivity, as it doses base and colorants directly into the empty cans.

With the optional COROB VG-SIM module, our newest patented high-speed dispensing system, productivity can increase by up to 30%, while simultaneous dispensing of base and colorants significantly reduces time.

Additionally, a wide range of hazardous chemicals can be handled safely thanks to COROB MODULA’s explosion-proof capacity.

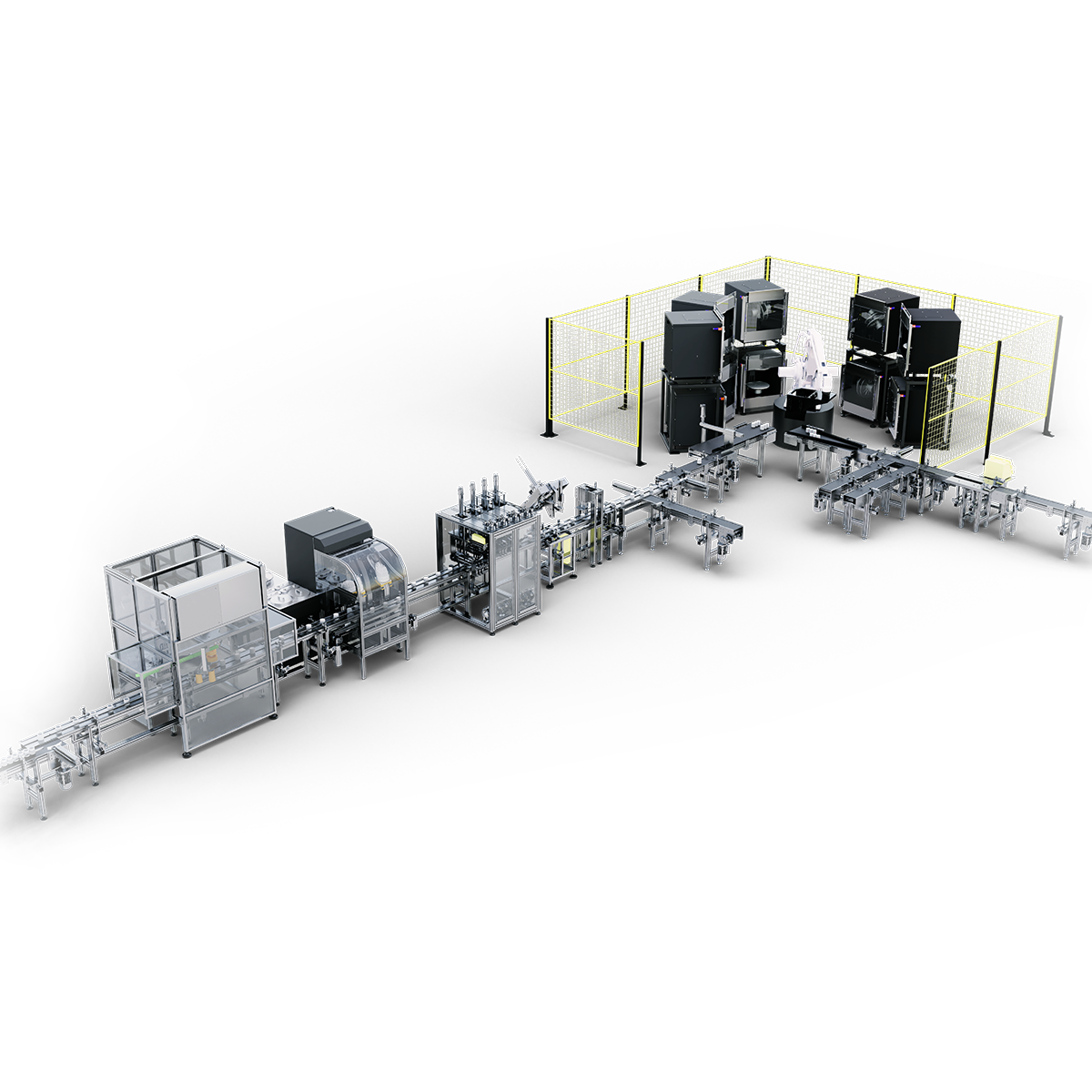

Layout

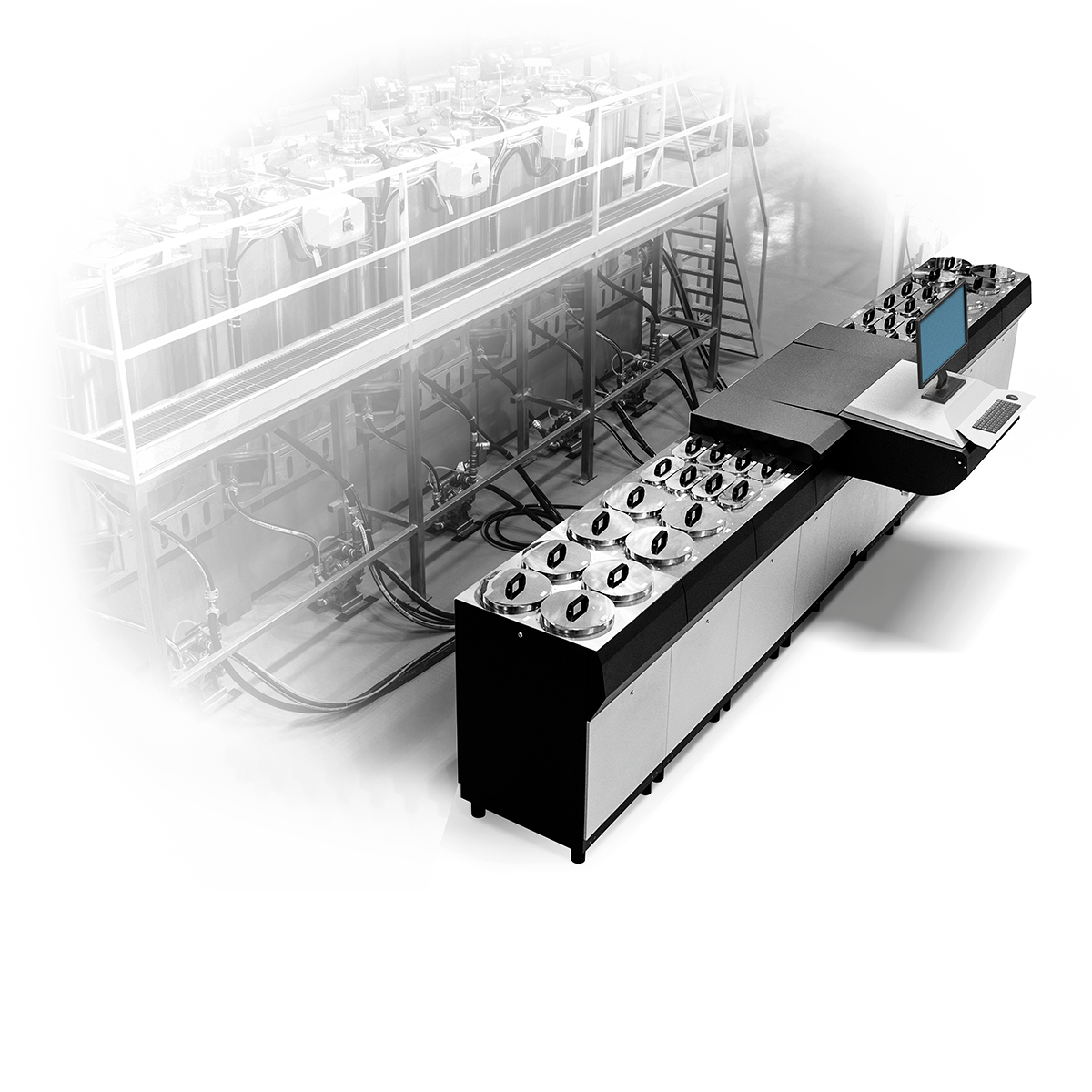

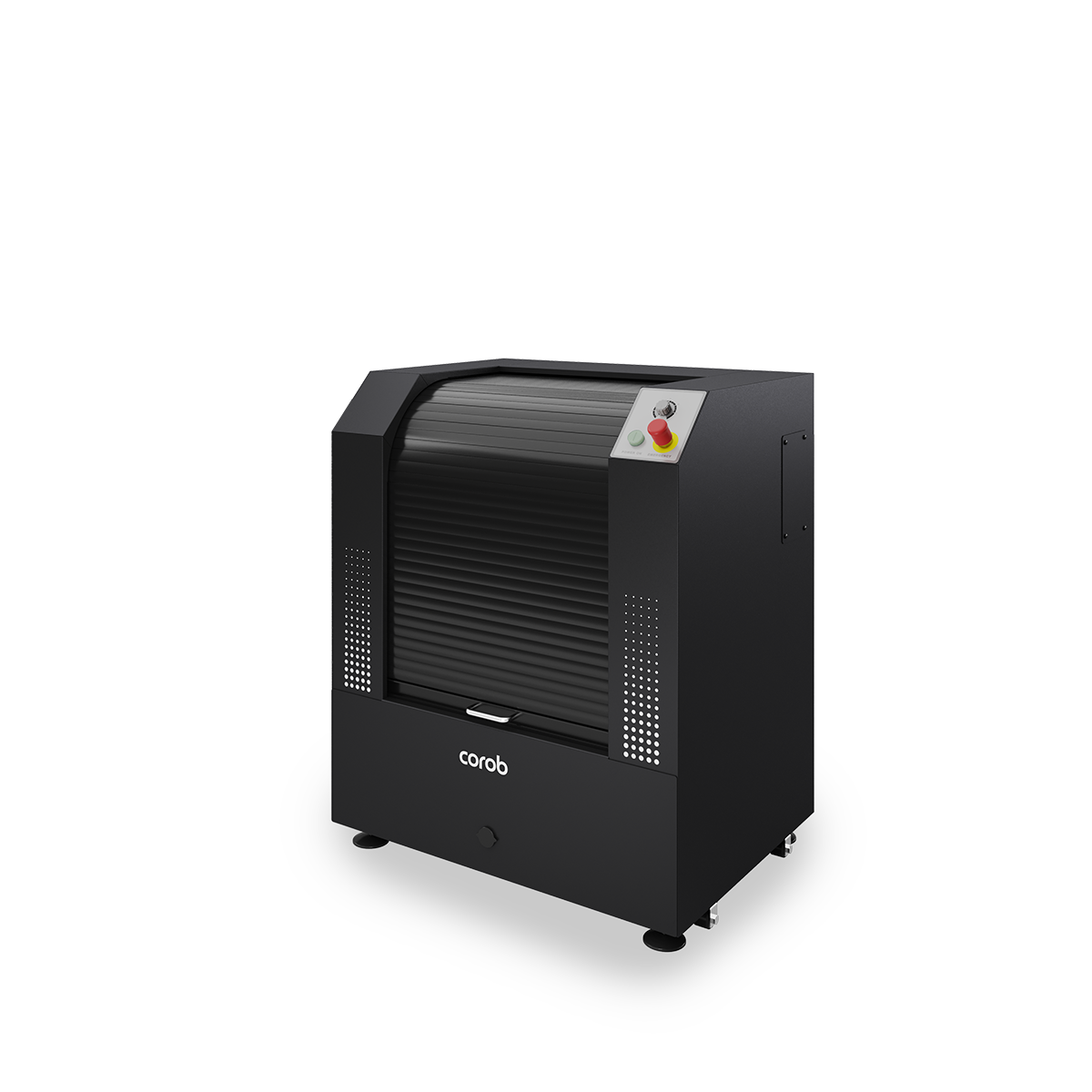

Discover the flexibility of the COROB MODULA product line, which offers a wide selection of configurations ranging from “in-line” to “U-shaped” layouts.

Our modules can be arranged in various combinations to provide the best solution to accommodate your production line.

To help you design a facility layout that meets your specific needs, our specialists submit multiple proposals, all with suitable configurations.

Module template and canister selection

Maximize the efficiency and throughput of your production line with the flexibility offered by COROB MODULA. With the ability to configure modules in a variety of combinations, you can find the best solution for your space and production needs.

Choose from a range of module templates to suit your specific requirements. MODULA can host canisters with up to 90 liters of capacity, making it the largest volume canister in the industry.

Gallery

Technical data

| MODULA VG | MODULA V | |

| Business environment | Large volume paint stores, production facilities | Large volume paint stores, production facilities |

| Volume output | High | High |

| Dispensing technology | BPG (bellows), Gear or in combination | BPG (bellows), Gear or in combination |

| Dispensing flow | Volumetric: Simultaneous Gravimetric: Sequential |

Simultaneous |

| Circuit flow rate [l/min]* | Internal: [BPG] HF 0.4; [Gear] HF 1.0 – STD 0.5 – LAB 0.16 / External: [AODD] up to 20 |

[BPG] HF 0.4; [Gear] STD 0.5 – HF 1.0 – LAB 0.16 |

| Minimum dispensed quantity [fl.oz.] (cc)* | STD 1/768 (0.039) – HF 1/384 (0.077) – LAB 1/1152 (0.026) | STD 1/768 (0.039) – HF 1/384 (0.077) – LAB 1/1152 (0.026) |

| Valve type | COROB 3-way electric valve: DN04/DN05 (volumetric system) – DN15 (gravimetric system) |

COROB 3-way electric valve or Integrated Nozzle Valve [INV] (with re-circulation) |

| Canister configurations | Internal: Up to 32 – External: Up to 10 | Up to 32 |

| Canister sizes [l] (q-G) | 3 (3 q) / 4 (4 q) / 6 (6 q) / 9 (9.5 q) / 15 (4 G) / 20 (5.3 G) / 35 (9.2 G) / 90 (24 G) [according to modules] | 3 (3 q) / 4 (4 q) / 6 (6 q) / 9 (9.5 q) / 15 (4 G) / 20 (5.3 G) / 35 (9.2 G) / 90 (24 G) [according to modules] |

| Colorant compatibility | Decorative and Industrial: Water [w], Universal and Solvent [s] | Decorative and Industrial: Water [w], Universal and Solvent [s] |

| Dimensions HxLxD [mm] (in) | 1410 x 1700 x 1450 (55.5 x 67 x 57) | 1210 x 1400 x 1350 (47.6 x 55.1 x 53.1) |

| Certification | CE / ETL [optional] / Explosion proof [optional] | CE / ETL [optional] / Explosion proof [optional] |

*Values highly affected by the nature of the colorants and their rheological properties.