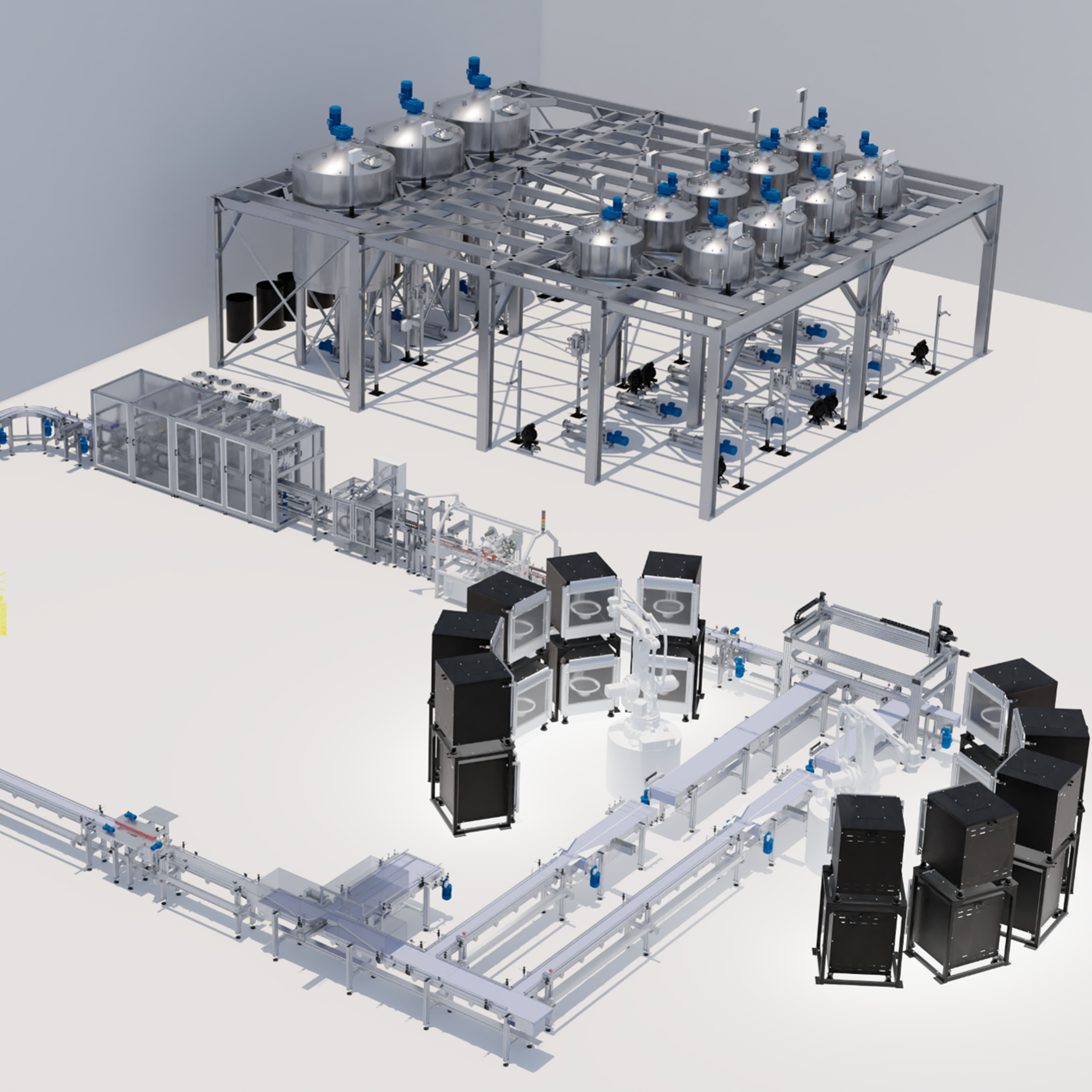

The COROB MS-RG Mixing Station is the ultimate productivity solution for high-volume can handling needs, offering unmatched mixing performance in a wide range of applications.

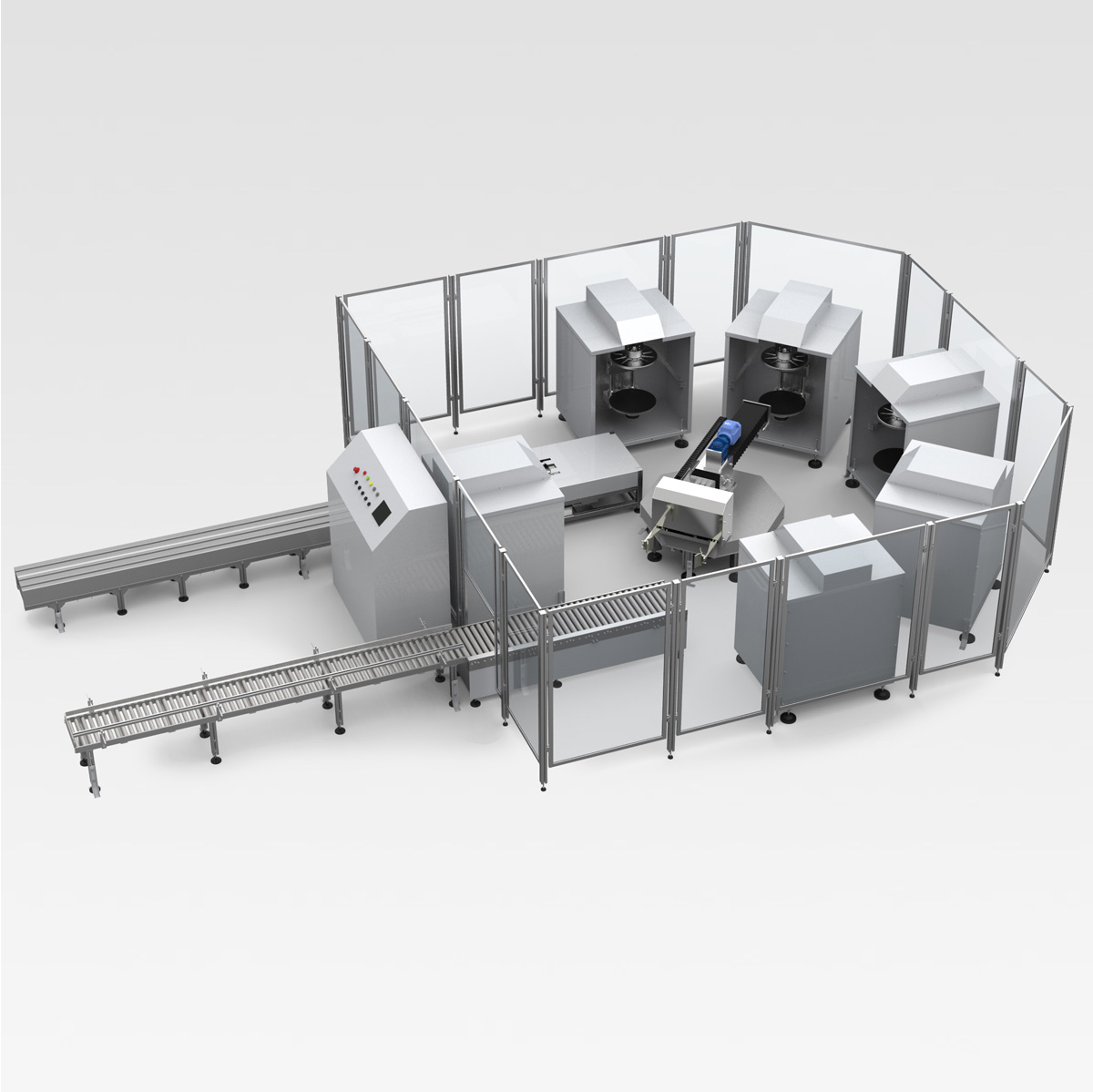

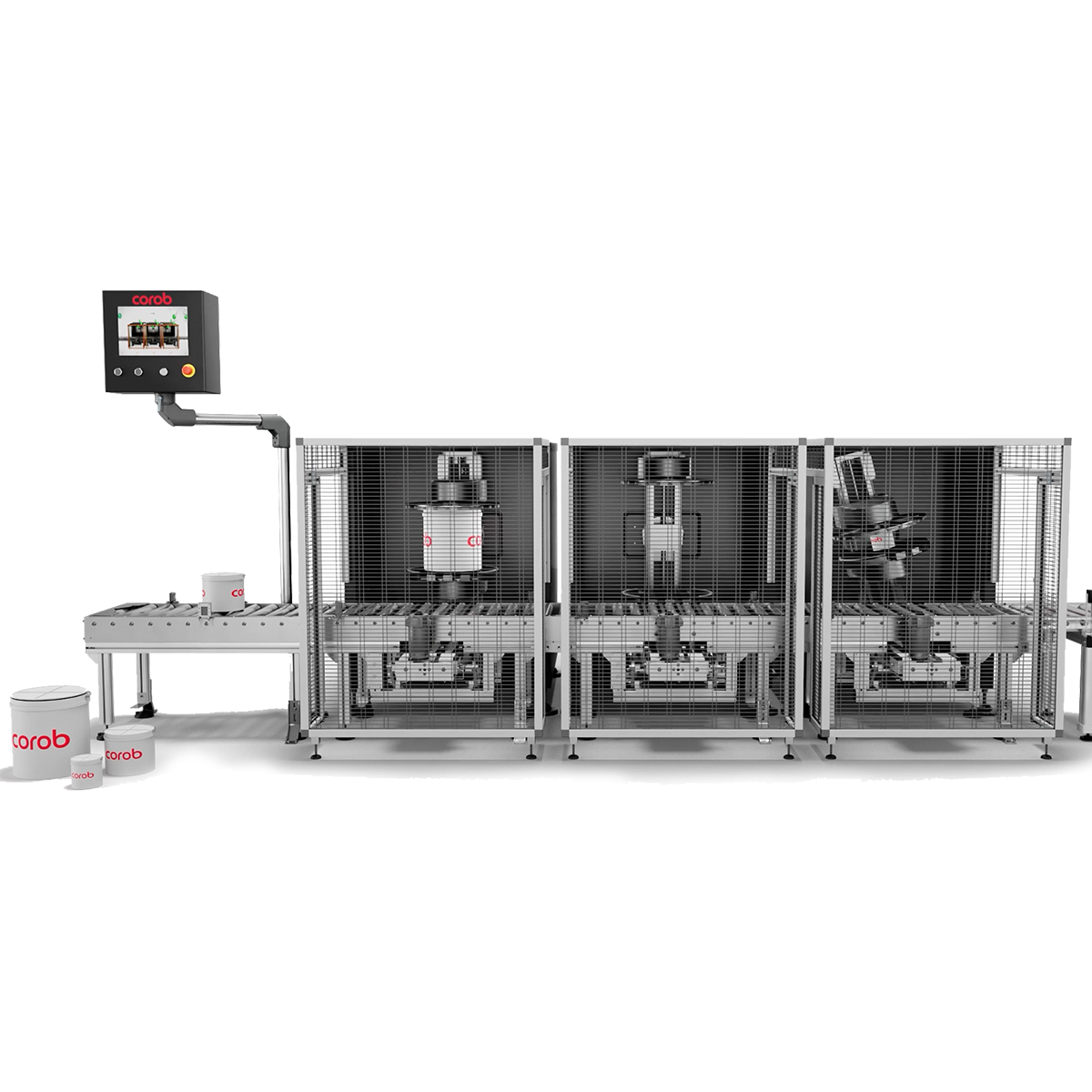

With up to ten heavy-duty gyroscopic mixers powered by 3HP direct drive mixing motors, the MS-RG delivers unparalleled efficiency and speed.

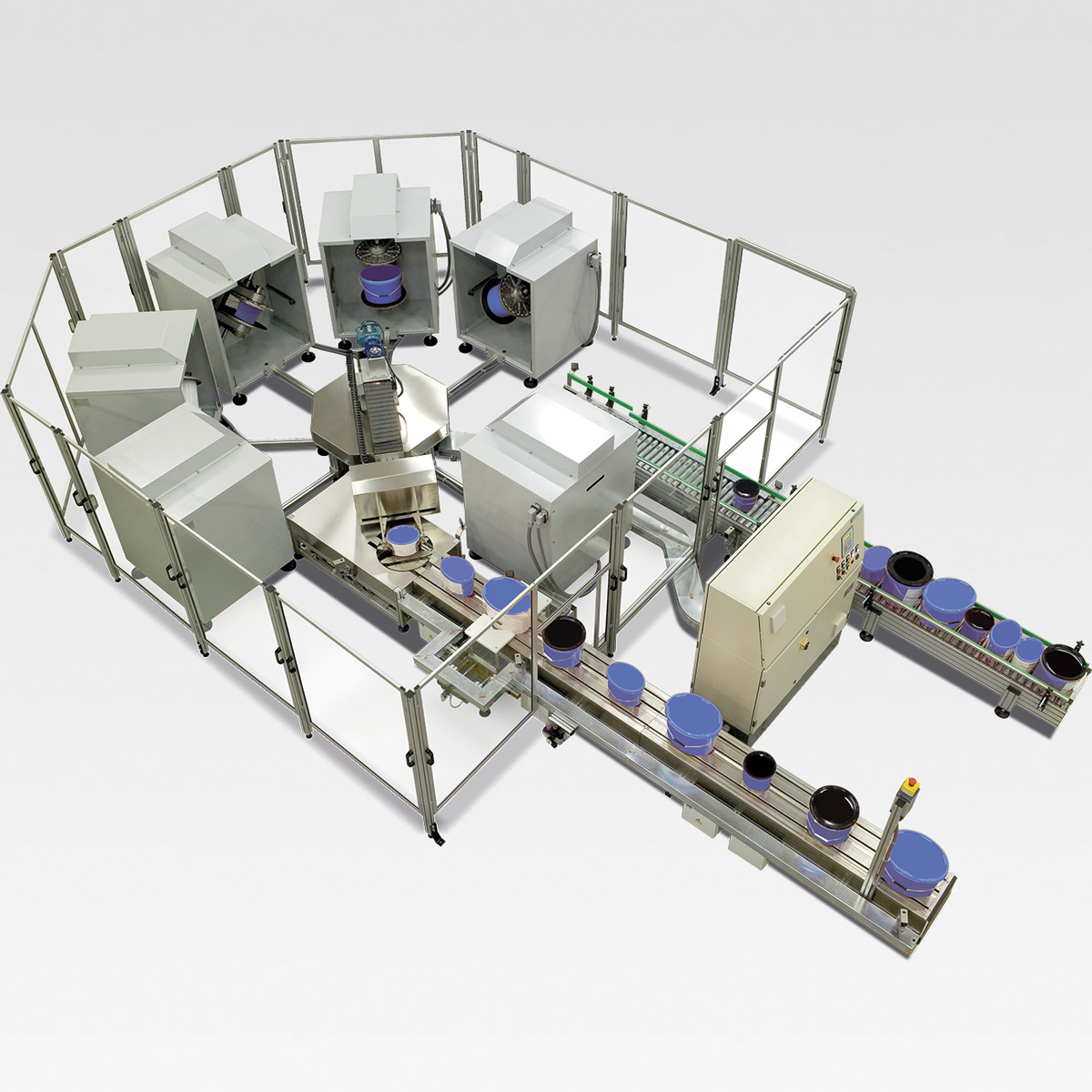

Fully automated conveyors easily handle pails weighing up to 40 kg/88 lbs, accommodating different can sizes and shapes simultaneously and automatically.

Operators can also customize mixing time and speed for each can individually, if desired, thanks to the MS-RG‘s intuitive controls.

During the mixing process, the can handles/bails are secured by a magnetic system, eliminating the need for tape or bungee cords and ensuring maximum safety and convenience.

The MS-RG solution delivers excellent results, increasing mixing performance while dramatically decreasing maintenance needs and reducing environmental noise. Choose the MS-RG for unmatched efficiency, productivity, and convenience in your mixing operations.