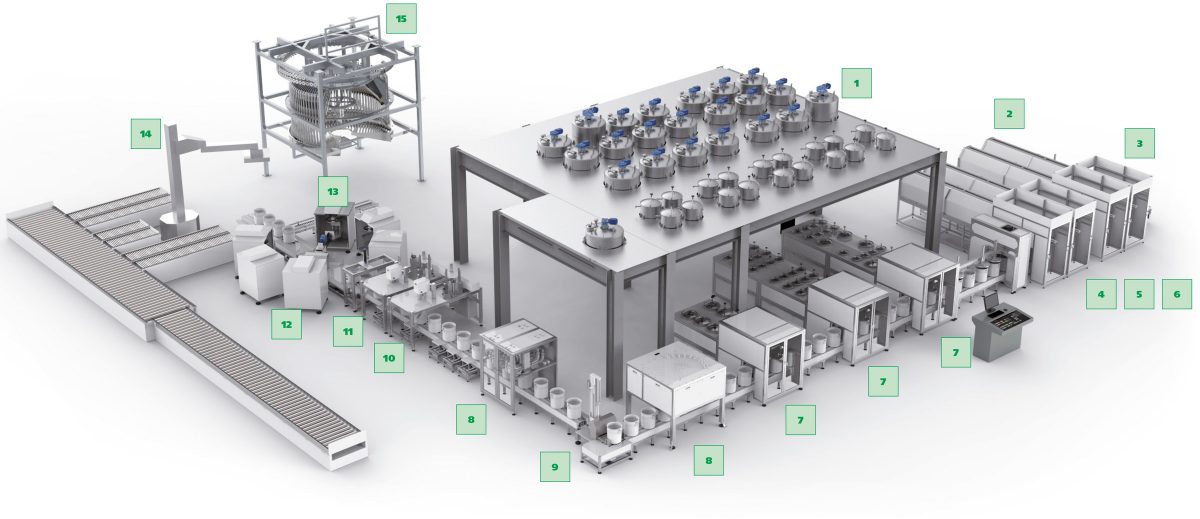

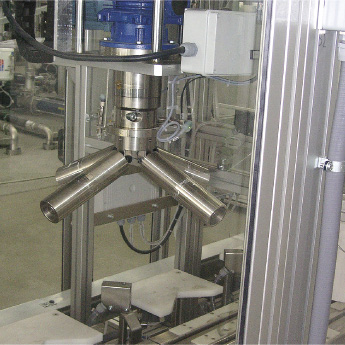

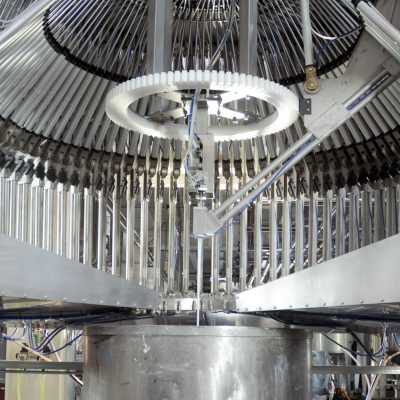

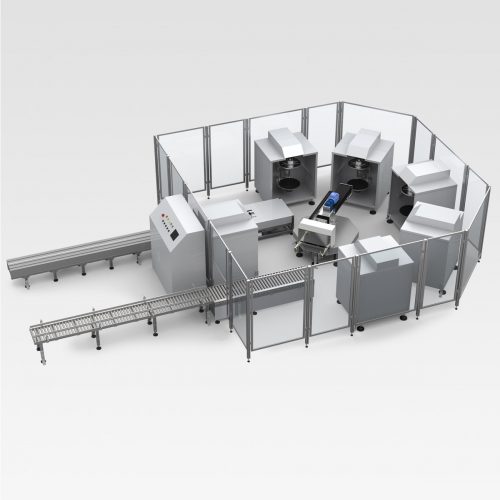

Our complete range of In-Can automated systems for high-performance and just-in-time production empowers a single operator to handle large numbers of customer orders with ease.

COROB’s fully automatic In-Can production lines are the perfect solution for companies that require flexibility to meet extensive and diverse daily demand for tinted paint or products.

By integrating a COROB In-Can system in strategic distribution centers, serving remote or demanding markets becomes a breeze.

You can reduce warehouse space, inventory, and working capital while increasing profitability by shortening delivery times.

The COROB solution is fully customizable to meet any budget or space requirement, allowing you to minimize costs, maximize production, and increase factory efficiencies with the automatic production line.