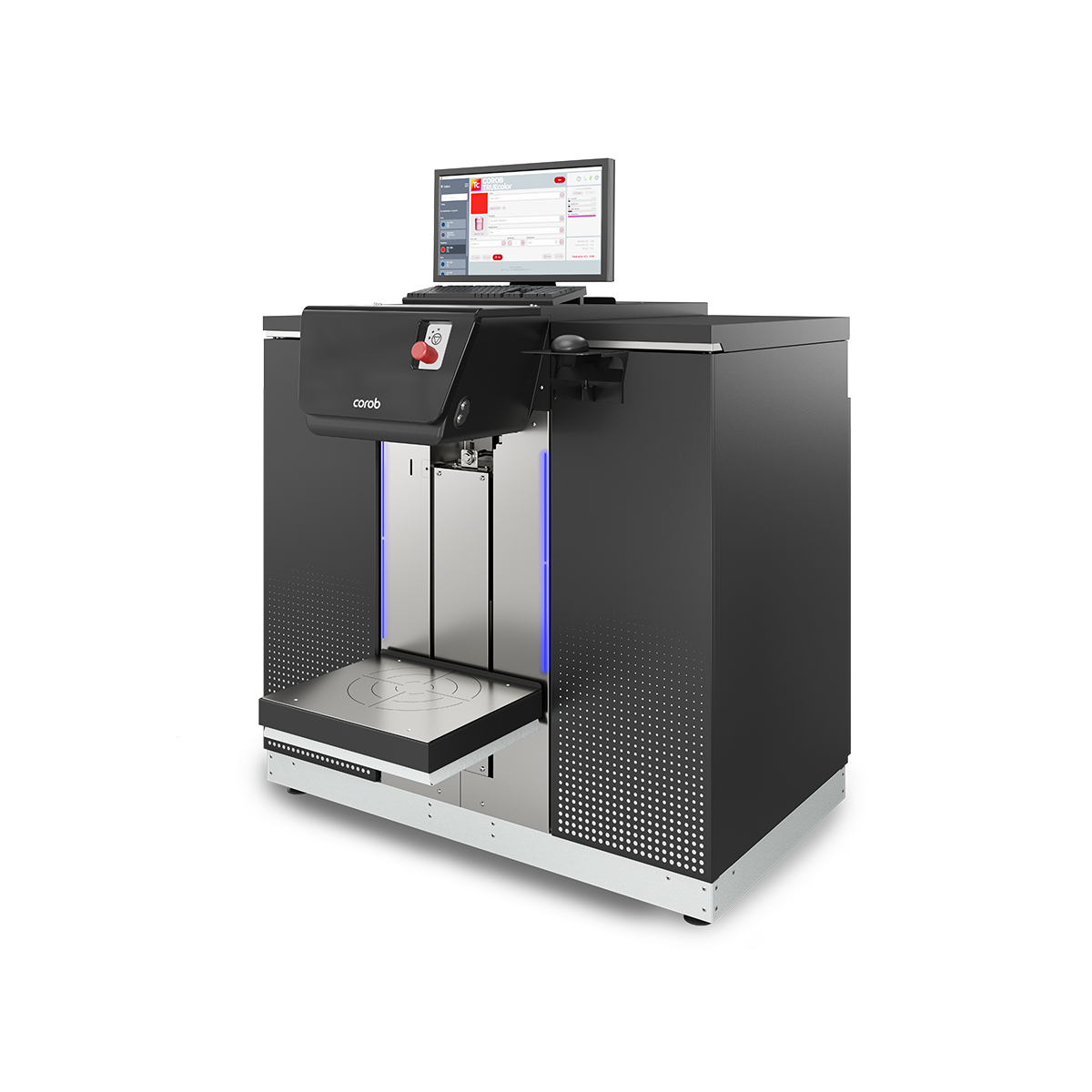

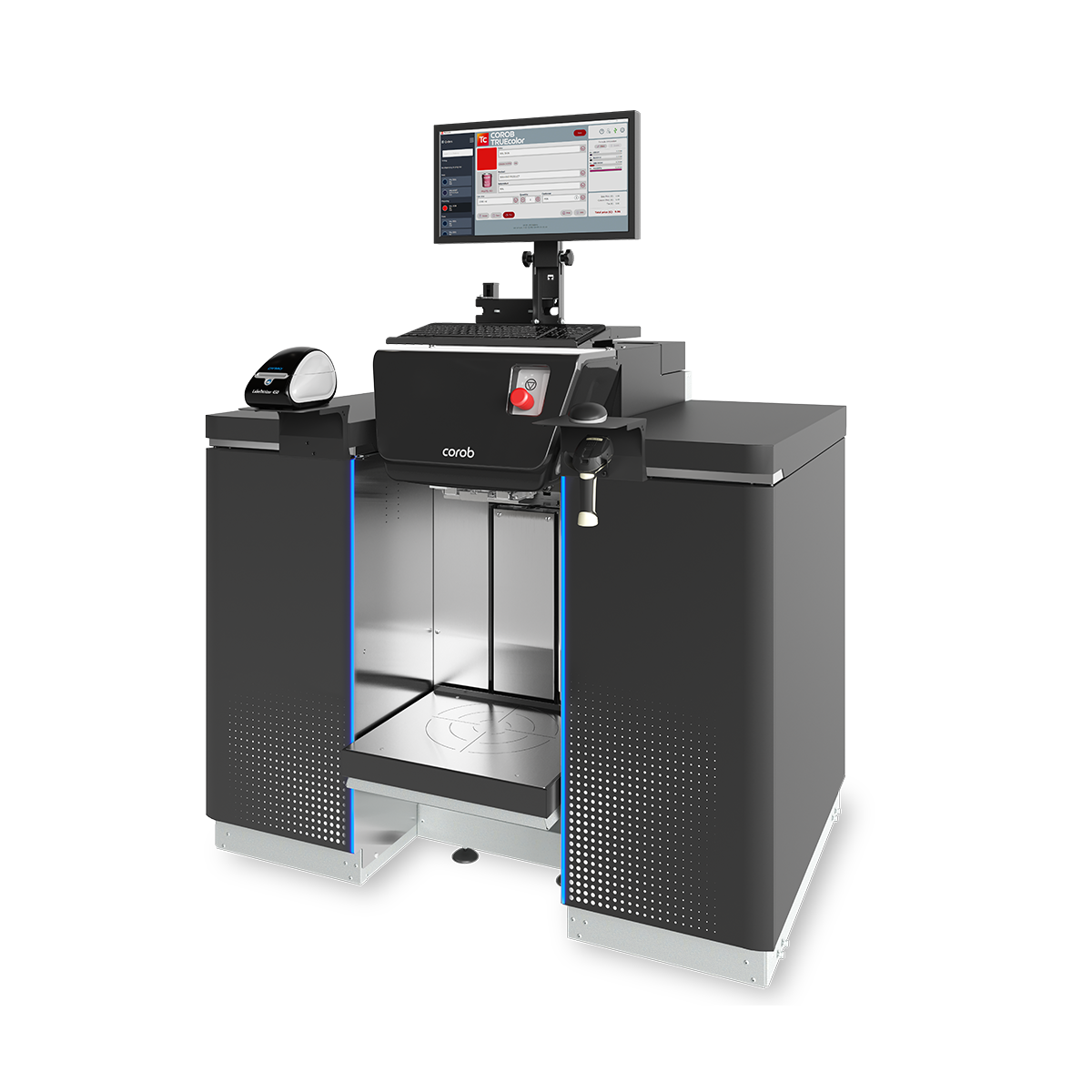

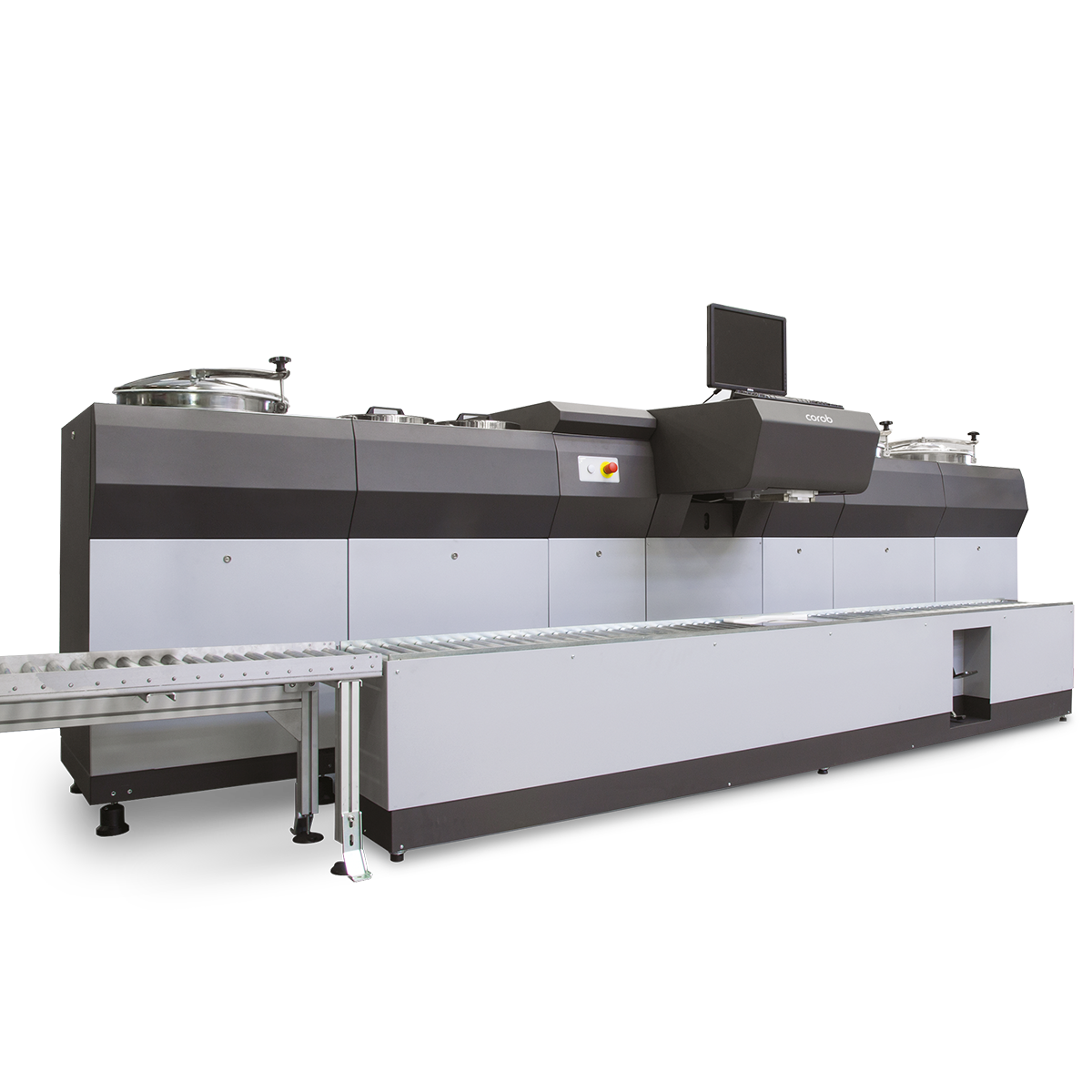

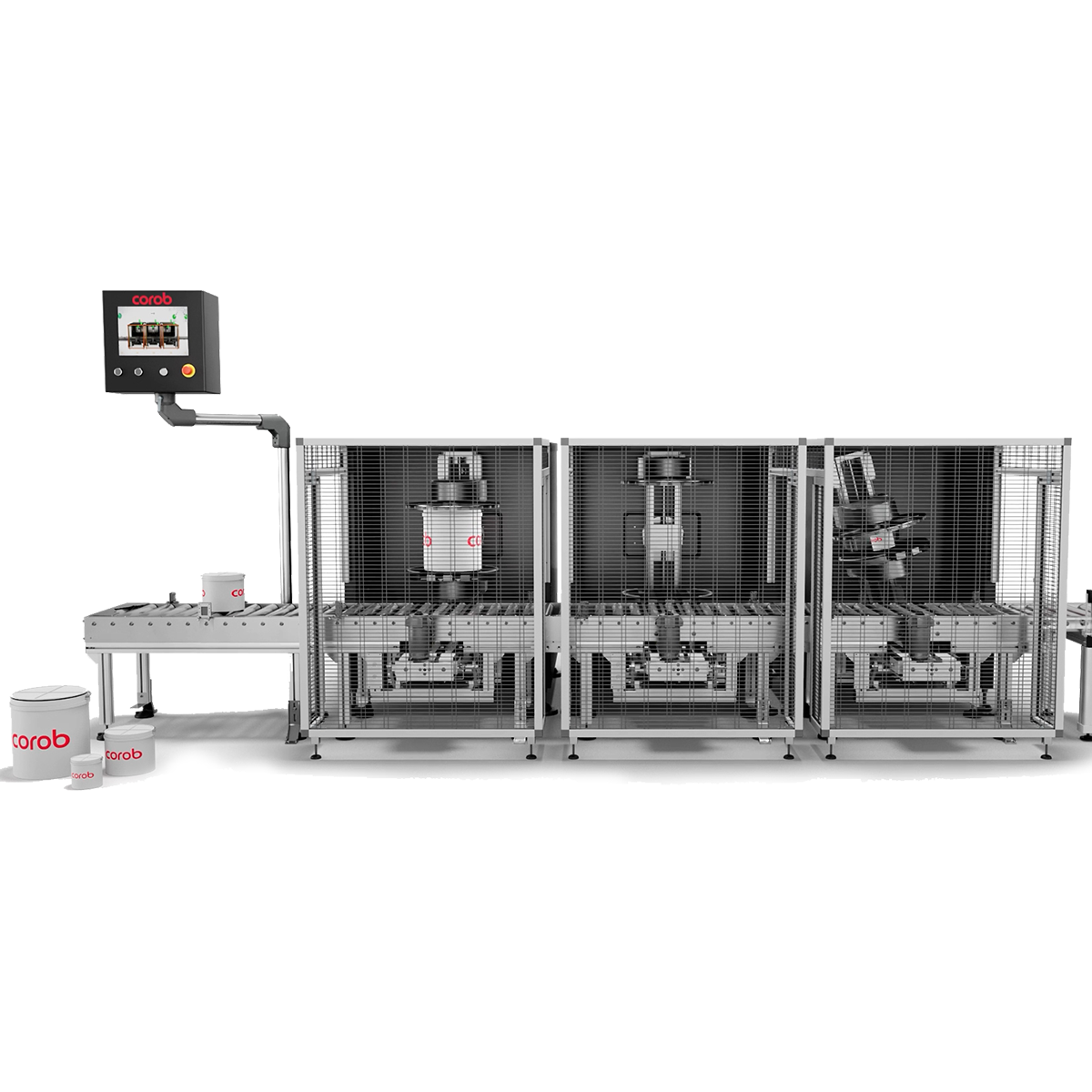

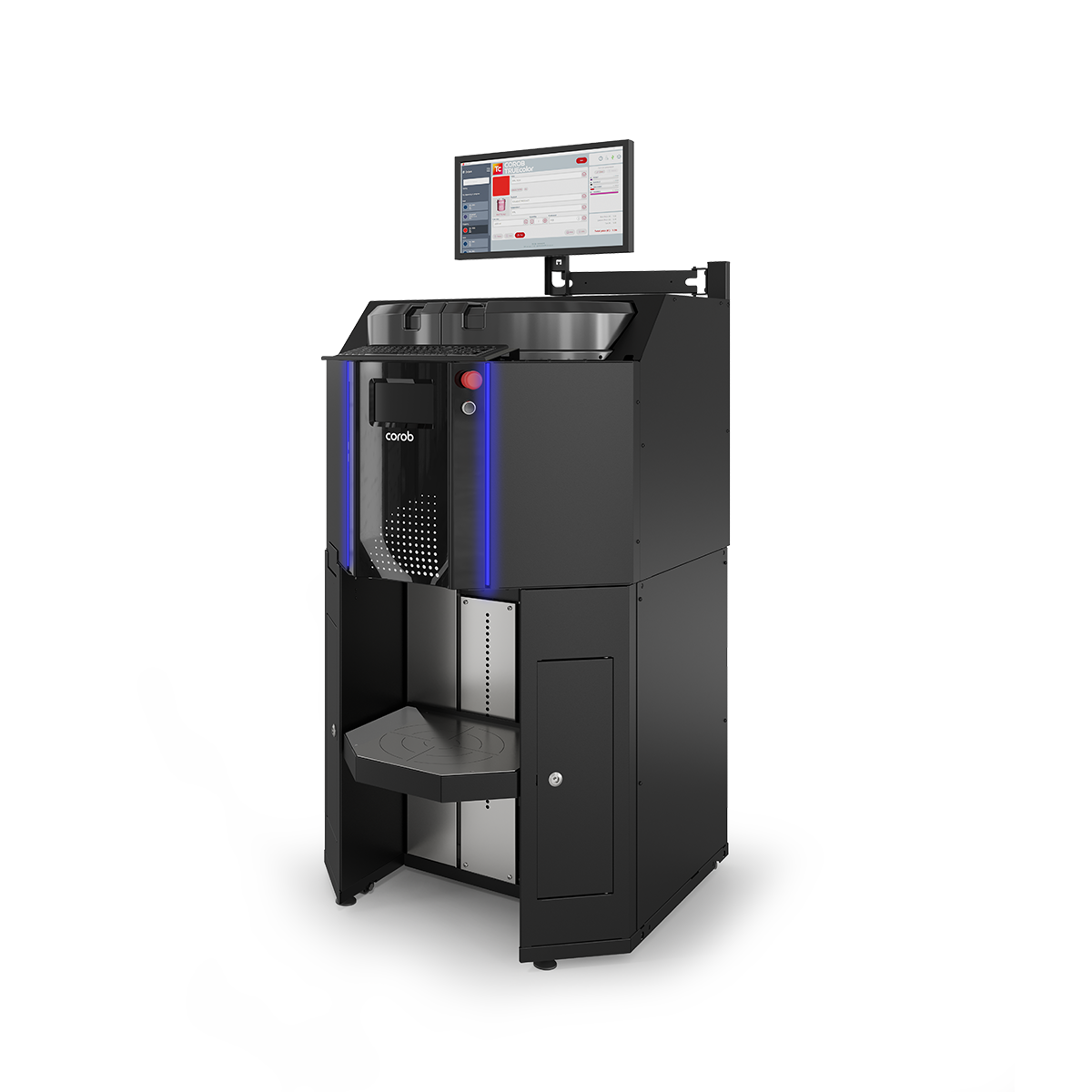

The NOVAFLOW N15J is a compact, automatic weight-based dispenser that redefines precision in small-batch production. Designed for medium productivity in limited spaces, it delivers exceptional gravimetric accuracy while occupying a minimal footprint.

Ideal for ink, coating, or chemical applications where precise weight-based dispensing is essential, the N15J offers a smart, space-efficient solution for your production needs.

With its compact design, the N15 dispenser excels in non-hazardous environments, efficiently producing small batches where space is limited.

It can produce 1-gallon batches in just 3 minutes*, even into containers with openings as small as 1.56”.

The N15J employs exclusive COROB Integrated Nozzle Valves and reliable Novaflow dispensing hardware and software, ensuring fast, precise, and repeatable results. Robust diaphragm pumps draw products directly from source containers, eliminating the mess and hassle of decanting into secondary vessels.

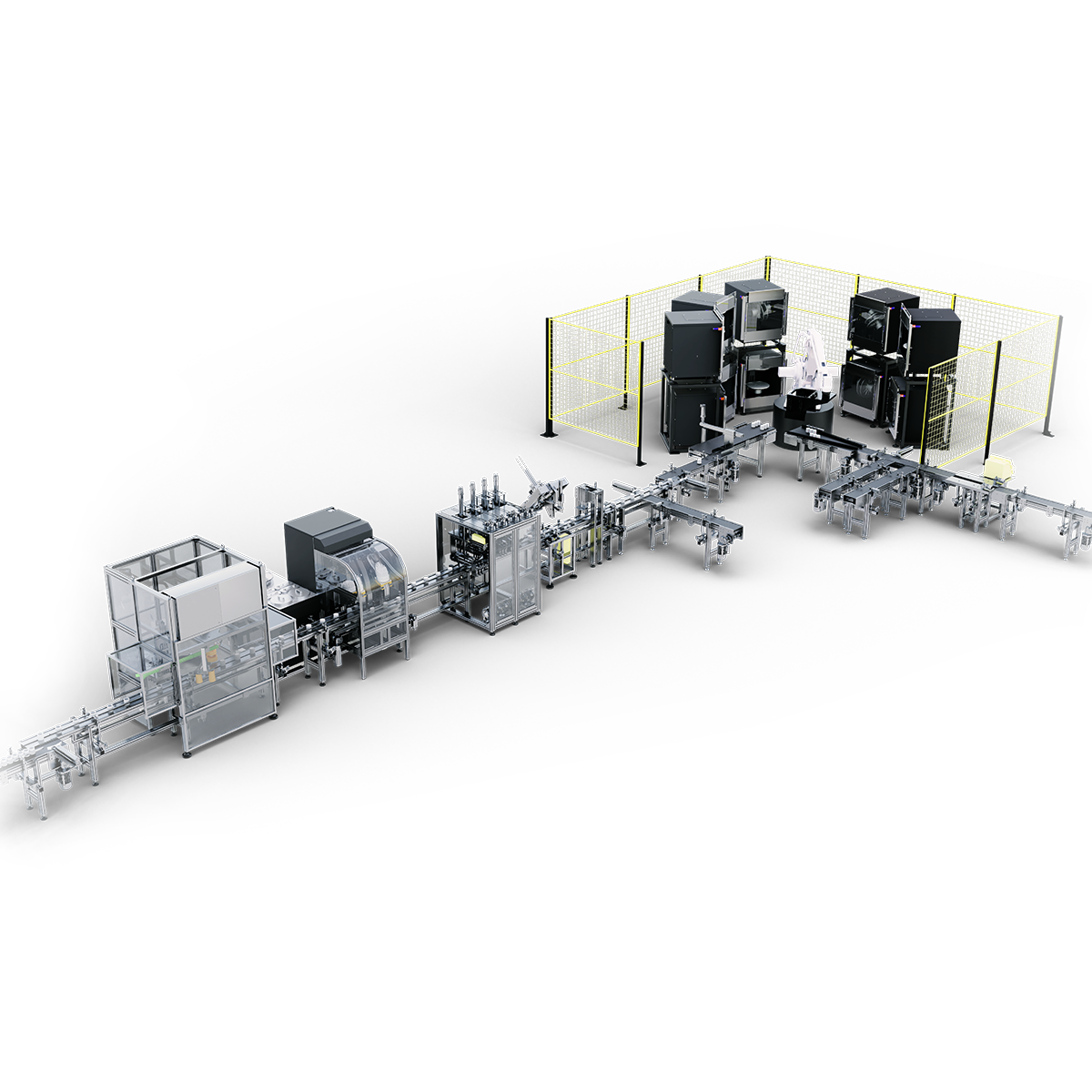

The system configuration includes 12 pails and 2 drum stations, with pumps and fluid circuit components selected to match the chemical properties and rheology of your products, guaranteeing optimal performance.

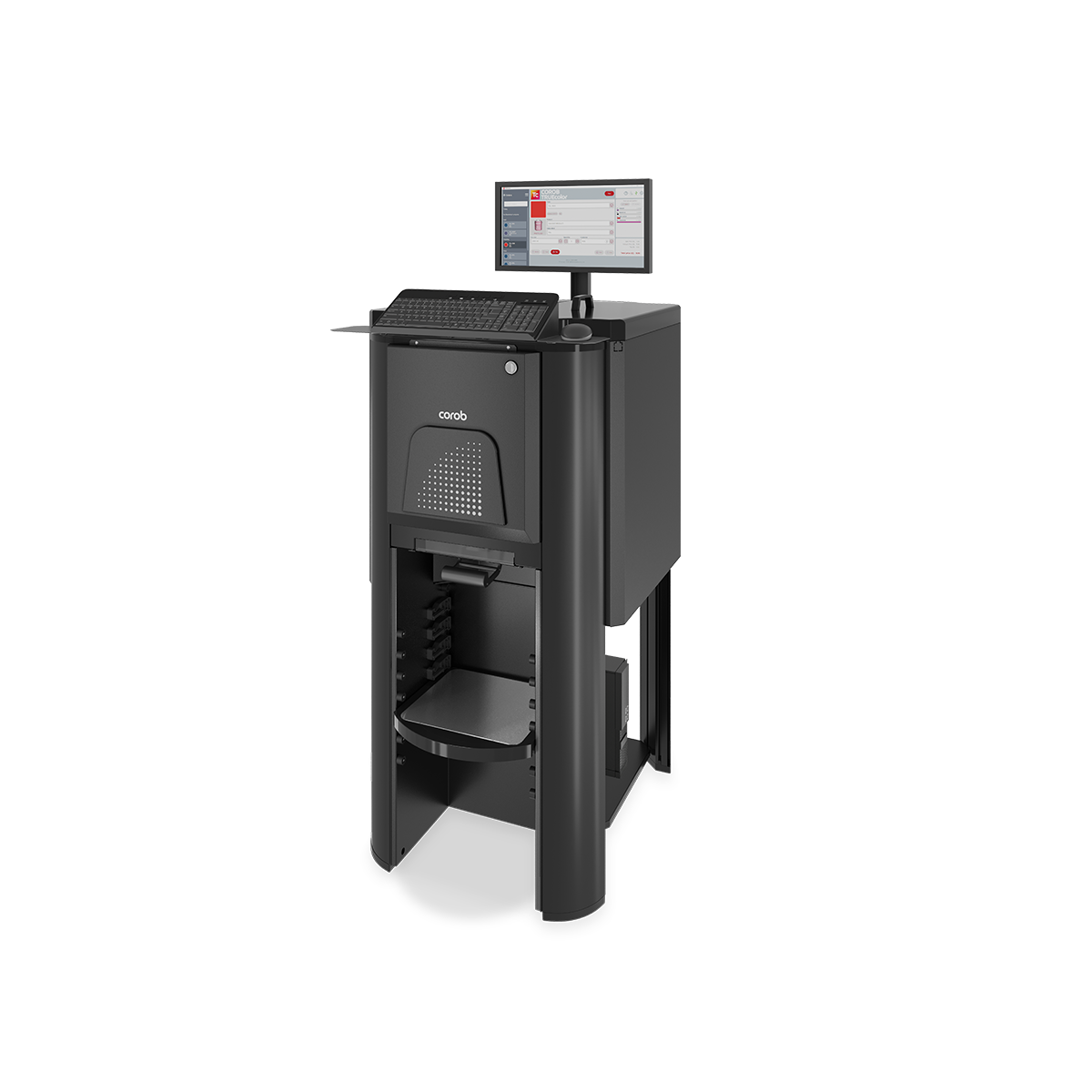

Powered by industry standard Novaflow dispensing and materials management software, the N15J provides complete control and visibility over product usage and production data.

Additionally, the system features an adjustable shelf for dispensing into containers of varying heights and includes a printer for automatic container labeling, ensuring reliable identification of finished products.

Choose the NOVAFLOW N15J for a compact, efficient, and highly accurate dispensing solution tailored to your small batch production needs.

*Values highly affected by the nature of the colorants and their rheological properties.

Technical data

| N15J [LV] | N15J [HV] | |

| Working environment | Non-hazardous | Non-hazardous |

| Application | Water and UV-based products | Water and UV-based products |

| Number of circuits | 14 | 14 |

| Type of circuits | 12 pails and 2 drums | 12 pails and 2 drums |

| Minimum container opening | 50 mm (2”) | 50 mm (2”) |

| Typical batch size | From 0.5 l to 4.5 l (0.15 – 1.2 USG) | From 0.5 l to 4.5 l (0.15 – 1.2 USG) |

| Product viscosity | 2000 CPS max. | 6000 CPS max. |

| Performance | 4–6 min per 4.5 l (1 USG) batch | 4–6 min per 4.5 l (1 USG) batch |

| Valve type | COROB Integrated Nozzle Valves (INV) | COROB 3-way valve |

| Accuracy* | starting from ± 0.5 g | starting from ± 0.5 g |

| Pump size | DN6 – ¼” (pail stations) / DN12 – 1/2” (drum stations) | DN6 – ¼” (pail stations) / DN12 – 1/2” (drum stations) |

| Valve cleaner | Autopad | Autocap |

| Scale | 15 kg (30 lb) | 15 kg (30 lb) |

| Cabinet | IP55 / NEMA 4x cabinet | IP55 / NEMA 4x cabinet |

| Safety compliance/certifications | CE, ESA, CSA, UL | CE, ESA, CSA, UL |

| Footprint | 52” X 93” (1.3 m X 2.4 m) | 52” X 93” (1.3 m X 2.4 m) |

* Values highly affected by the nature of the products and their rheological properties. Values dependant on valve size and scale type combination.

Note: data refers to machine base configuration, values may vary according to different specifications.

![T200 [S] Turntable dispenser piston small](https://www.corob.com/wp-content/uploads/2025/12/T200-S-Turntable-dispenser-piston-small.png)