COSMETICS & BEAUTY

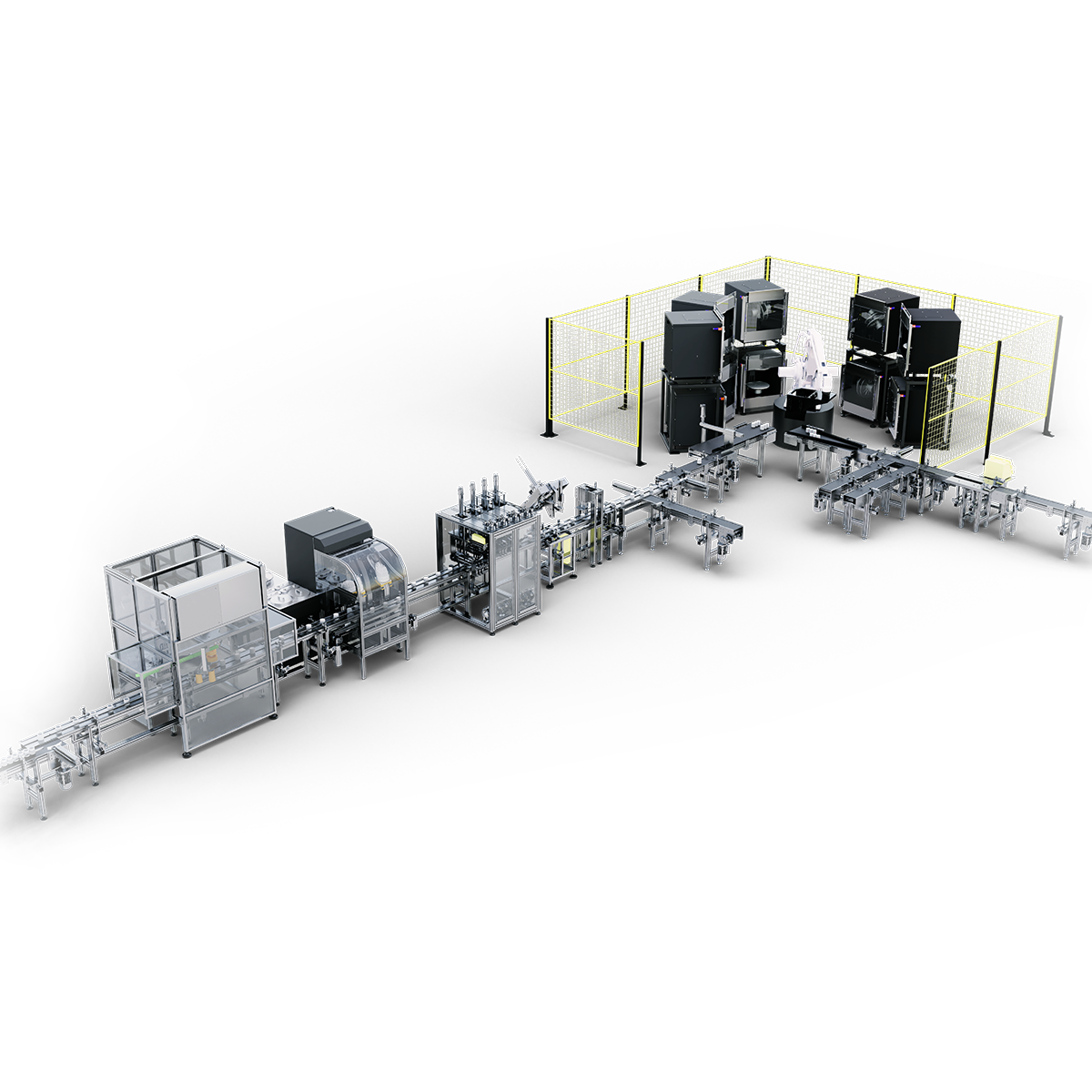

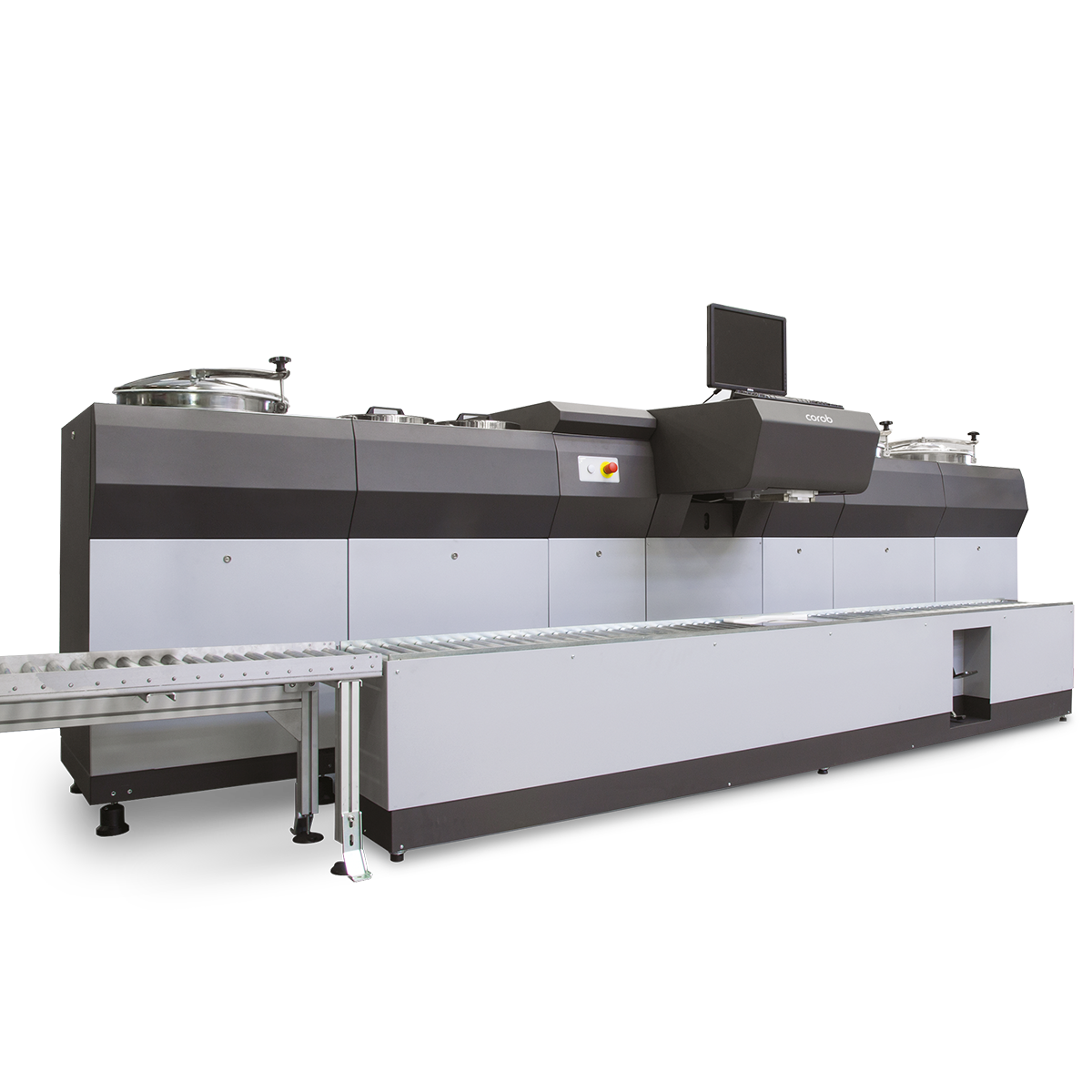

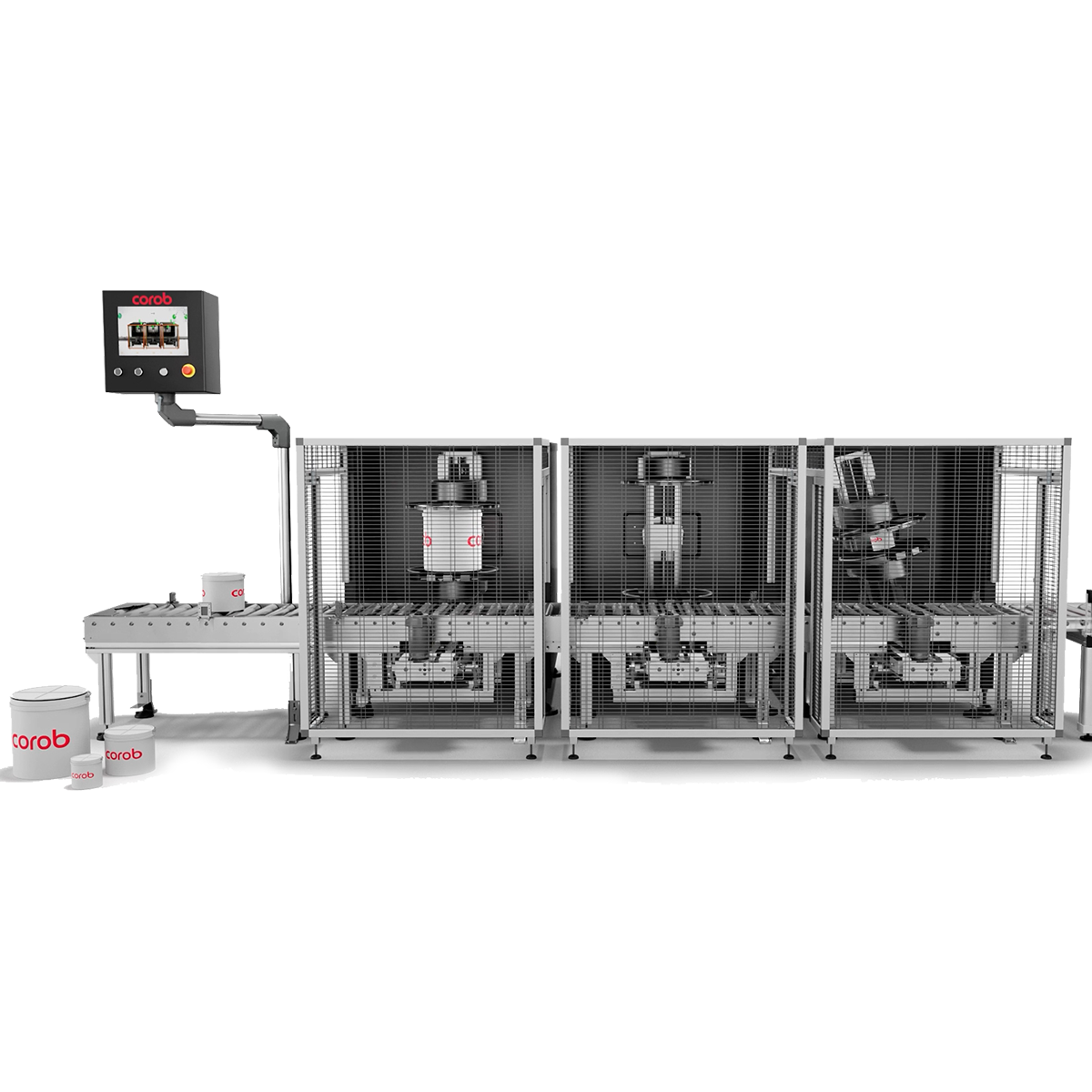

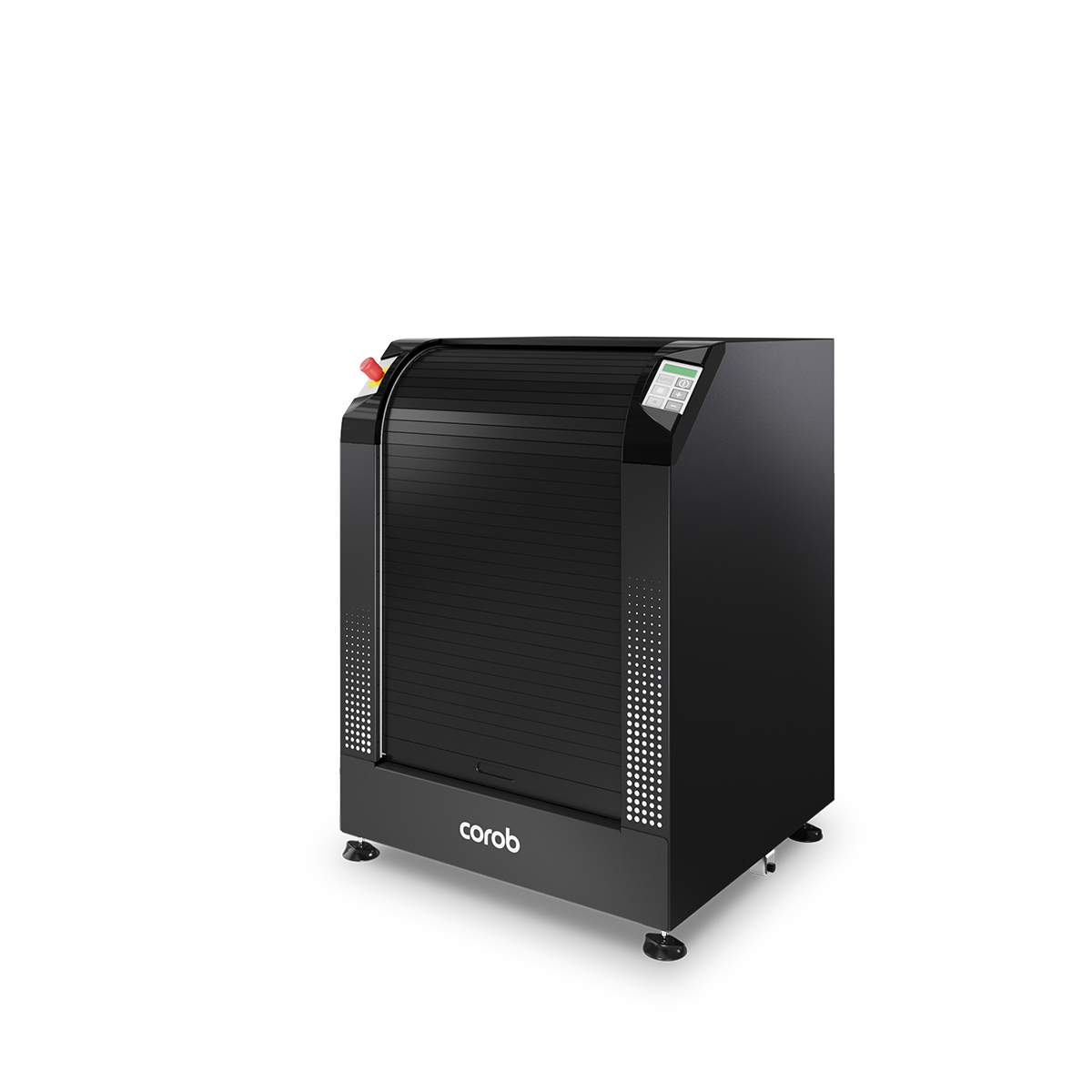

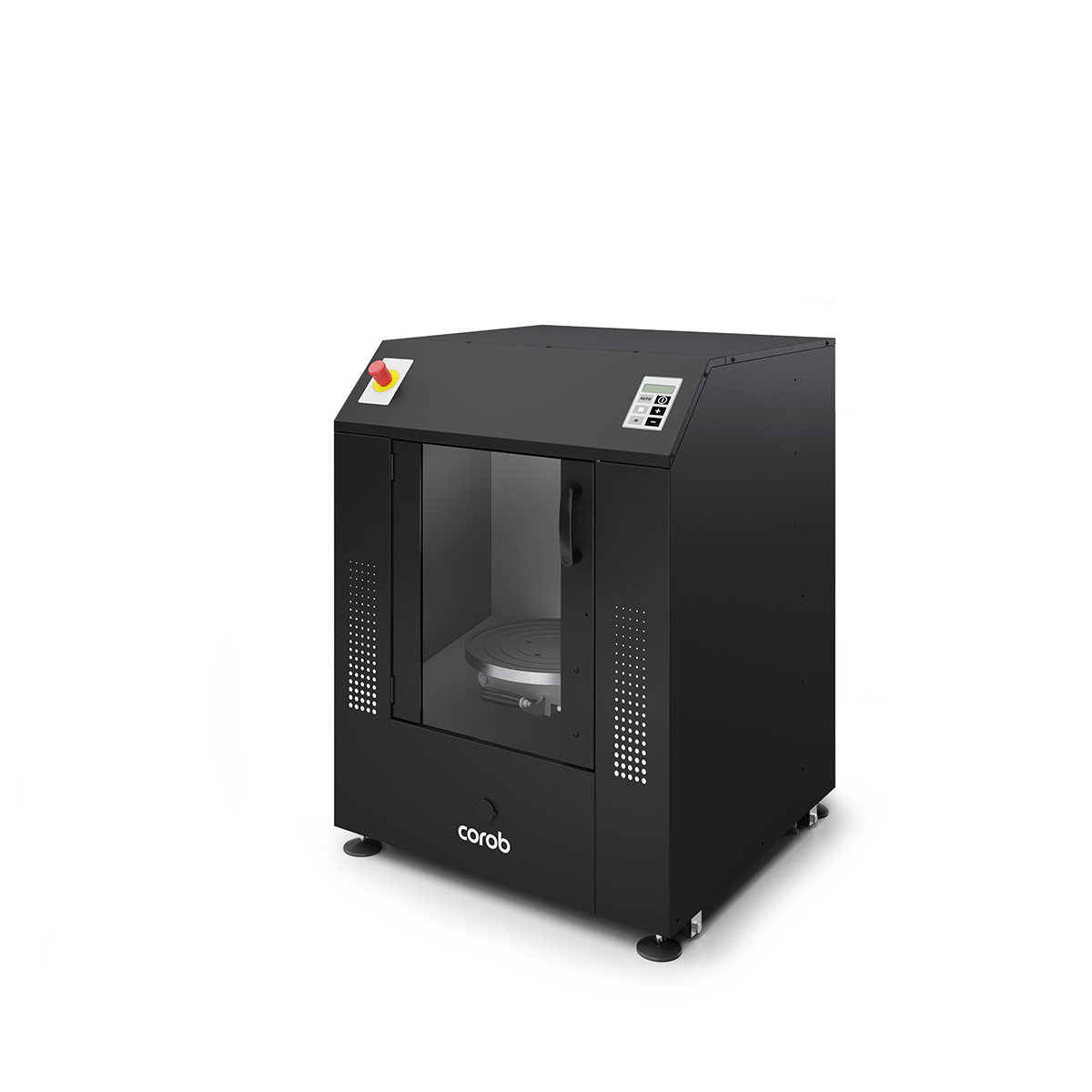

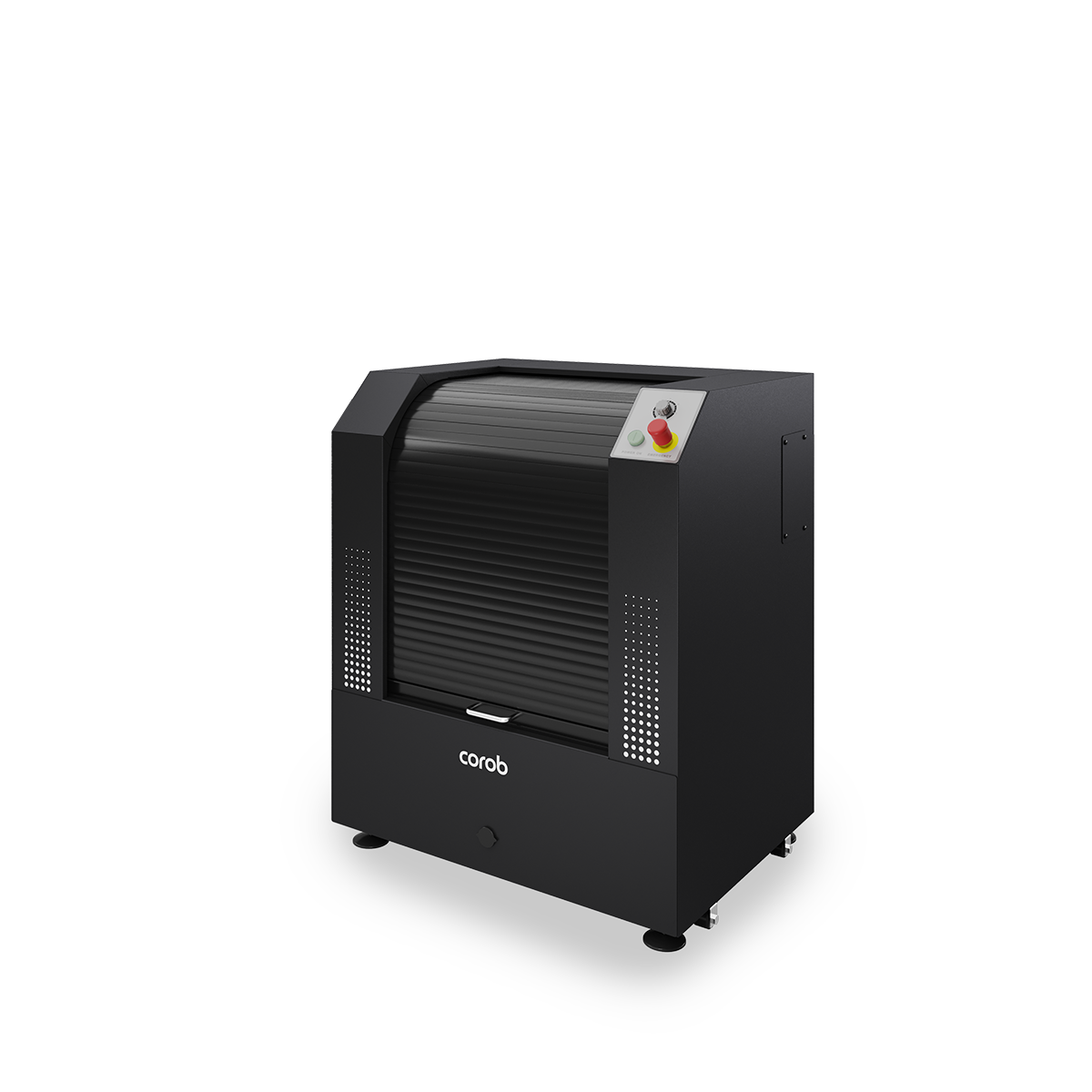

COROB technology is ideally suited for the cosmetics and beauty industry, where precision, safety, and flexibility are essential. Our dispensing and dosing systems are designed to handle a wide variety of ingredients—ranging in texture, viscosity, and color—to produce consistent, high-quality final products.

Cosmetic formulations often require:

Whether for R&D labs, pilot plants, or full-scale production, COROB systems can help cosmetic manufacturers streamline operations, reduce waste, and accelerate time-to-market—without compromising on quality or compliance.

COROB solutions also support:

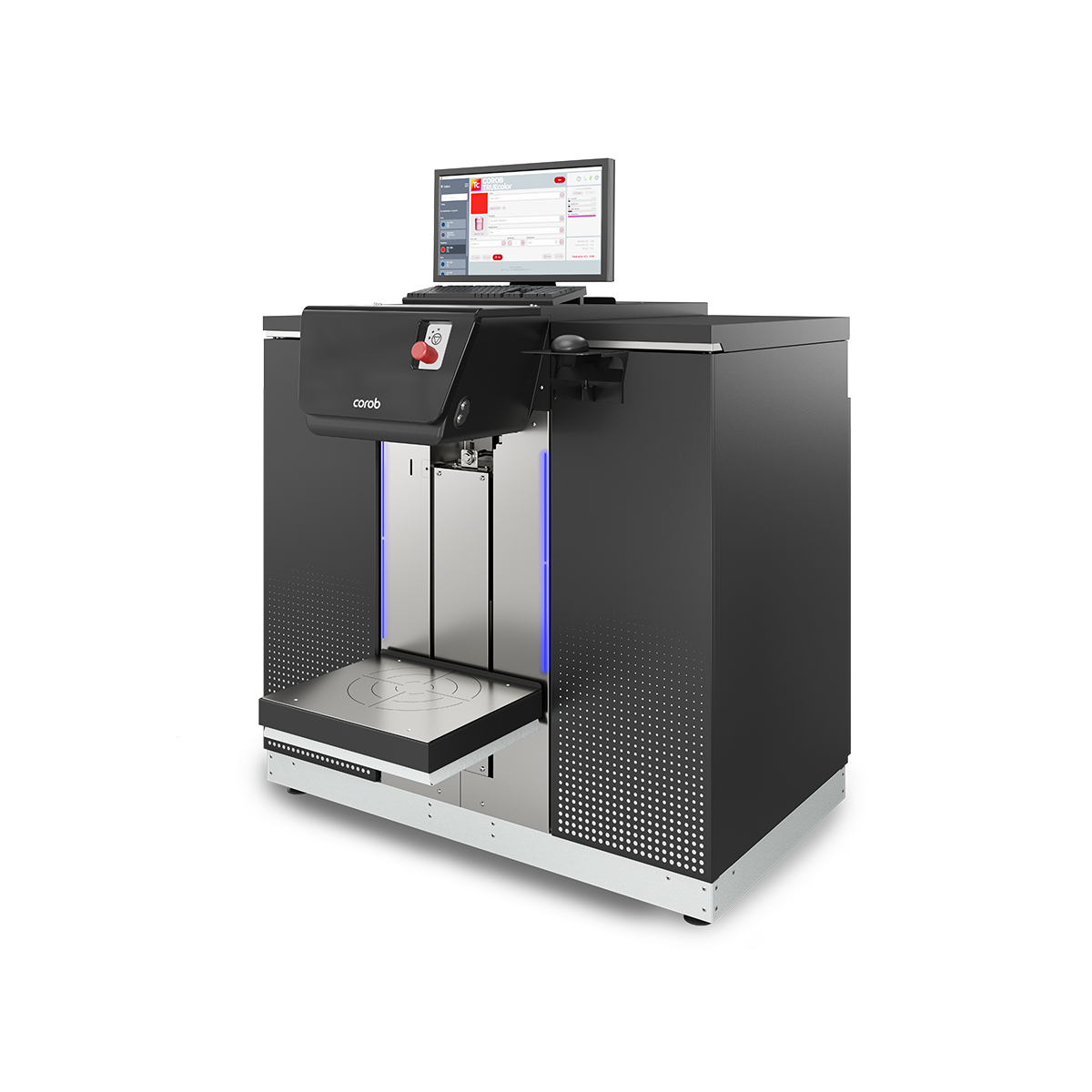

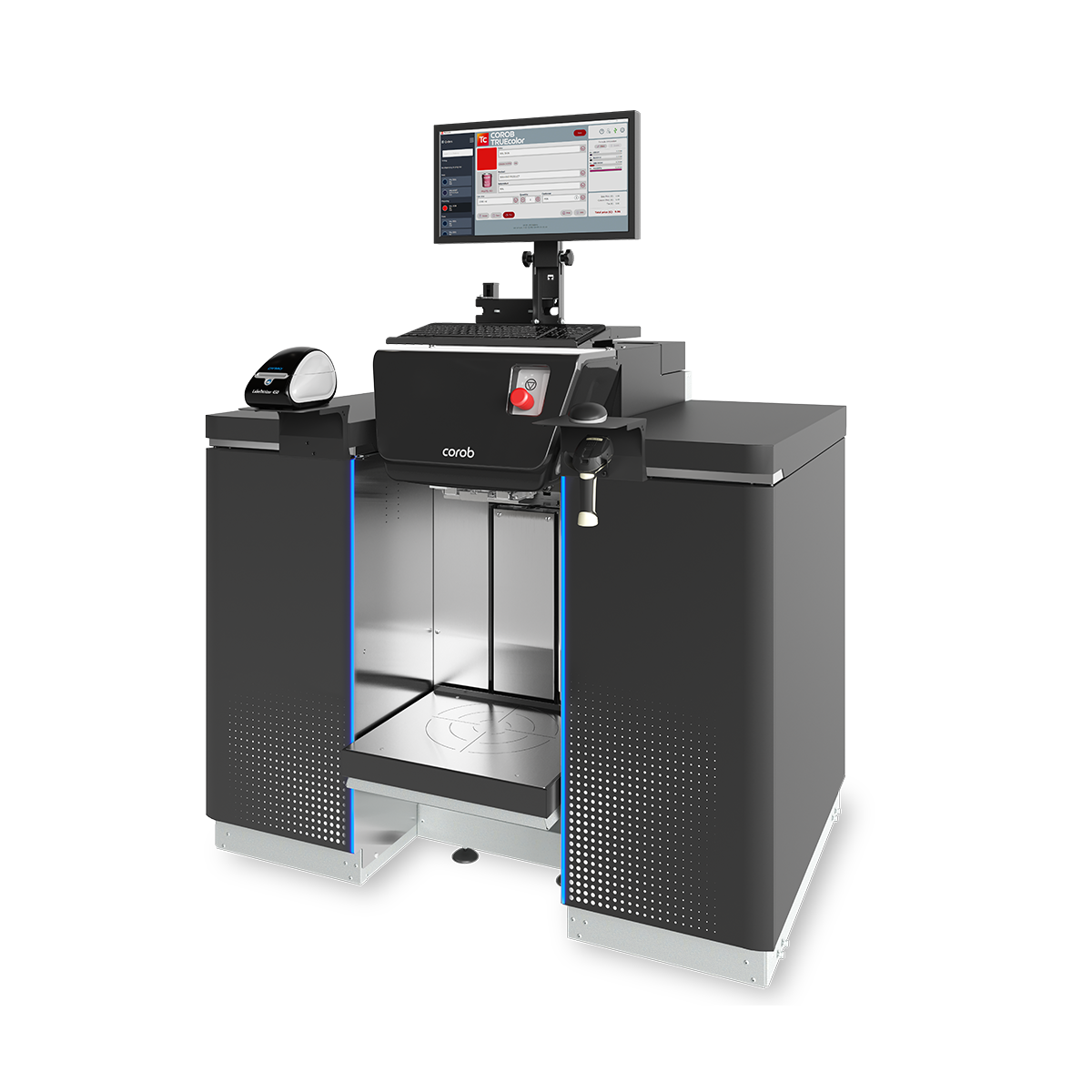

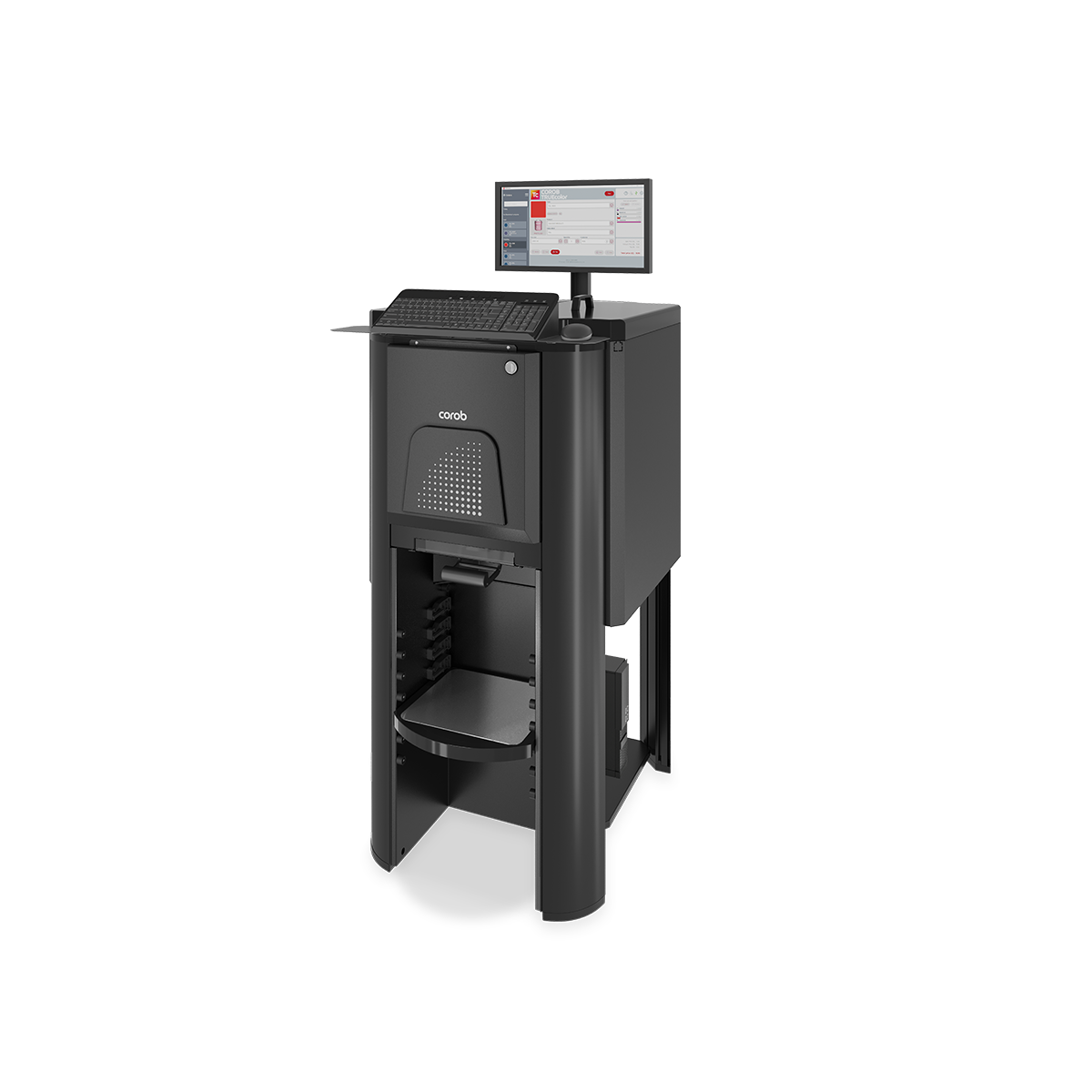

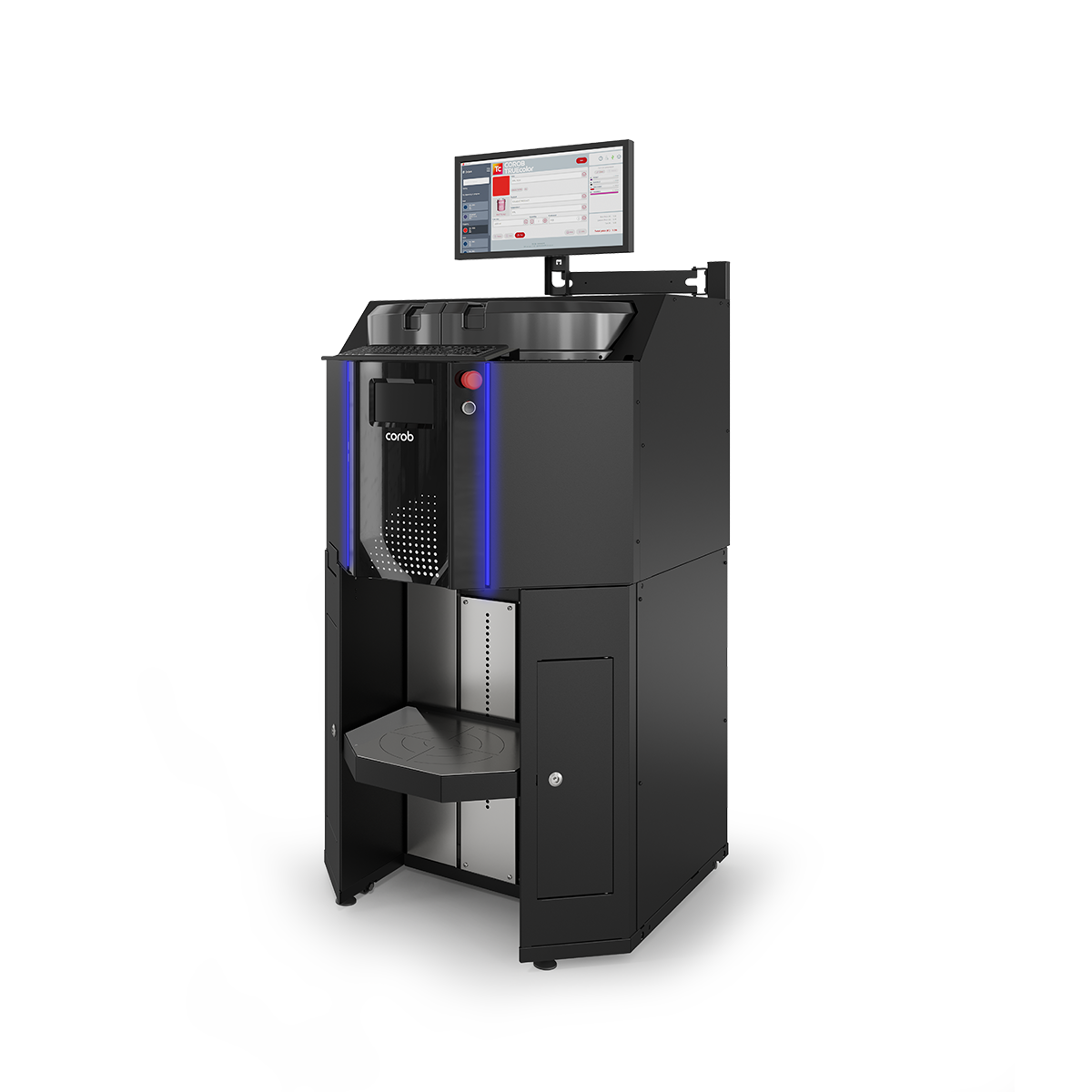

![T200 [S] Turntable dispenser piston small](https://www.corob.com/wp-content/uploads/2025/12/T200-S-Turntable-dispenser-piston-small.png)