LEATHER

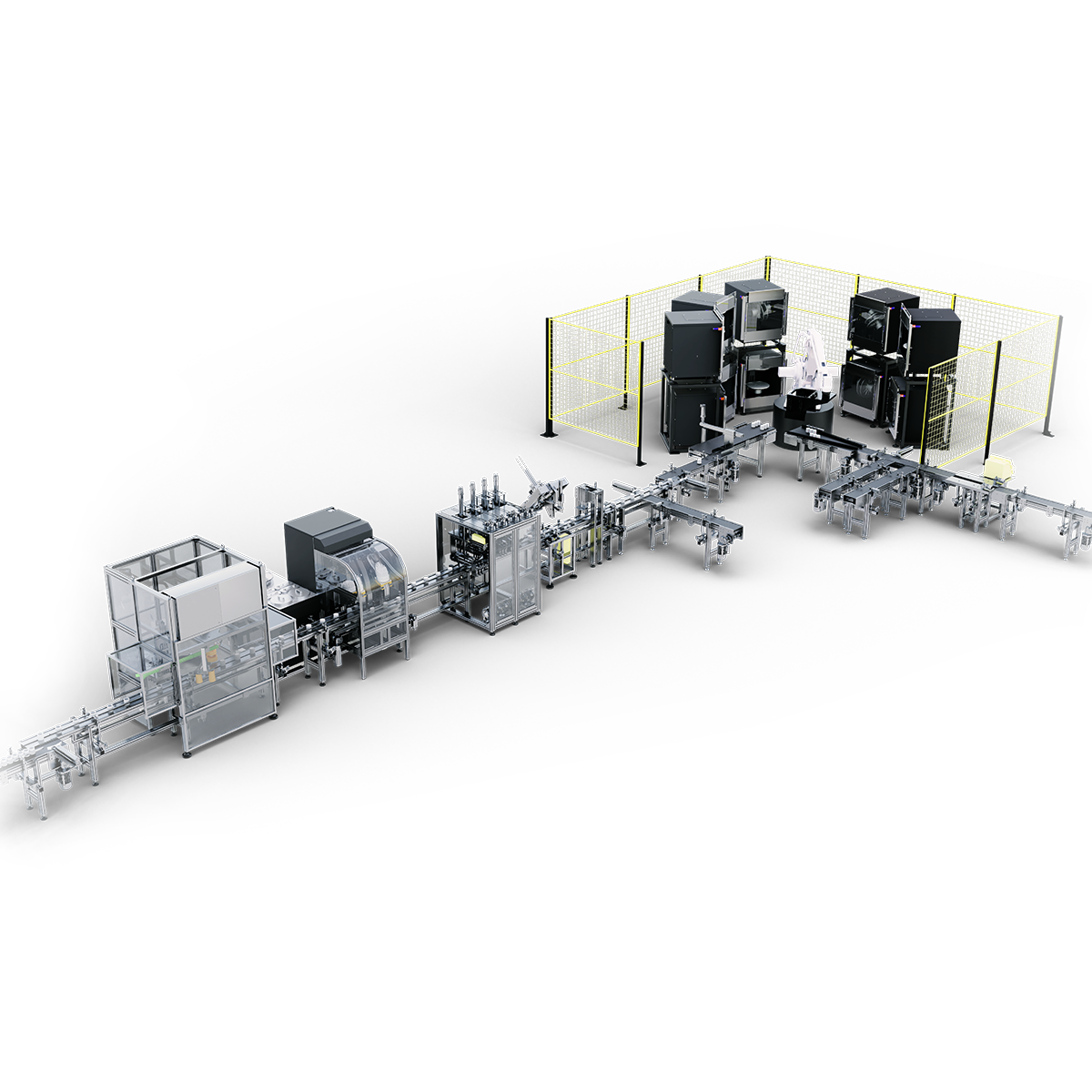

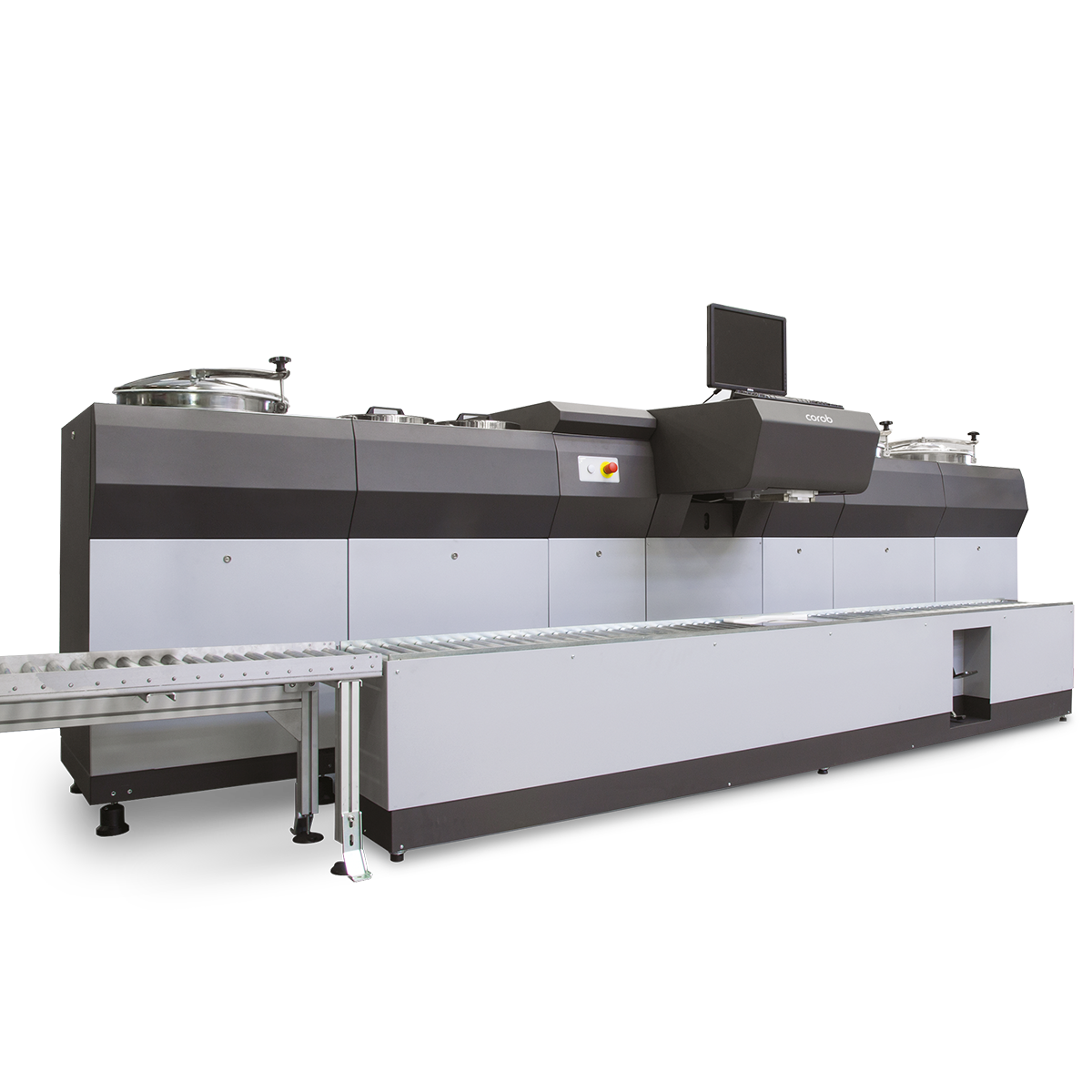

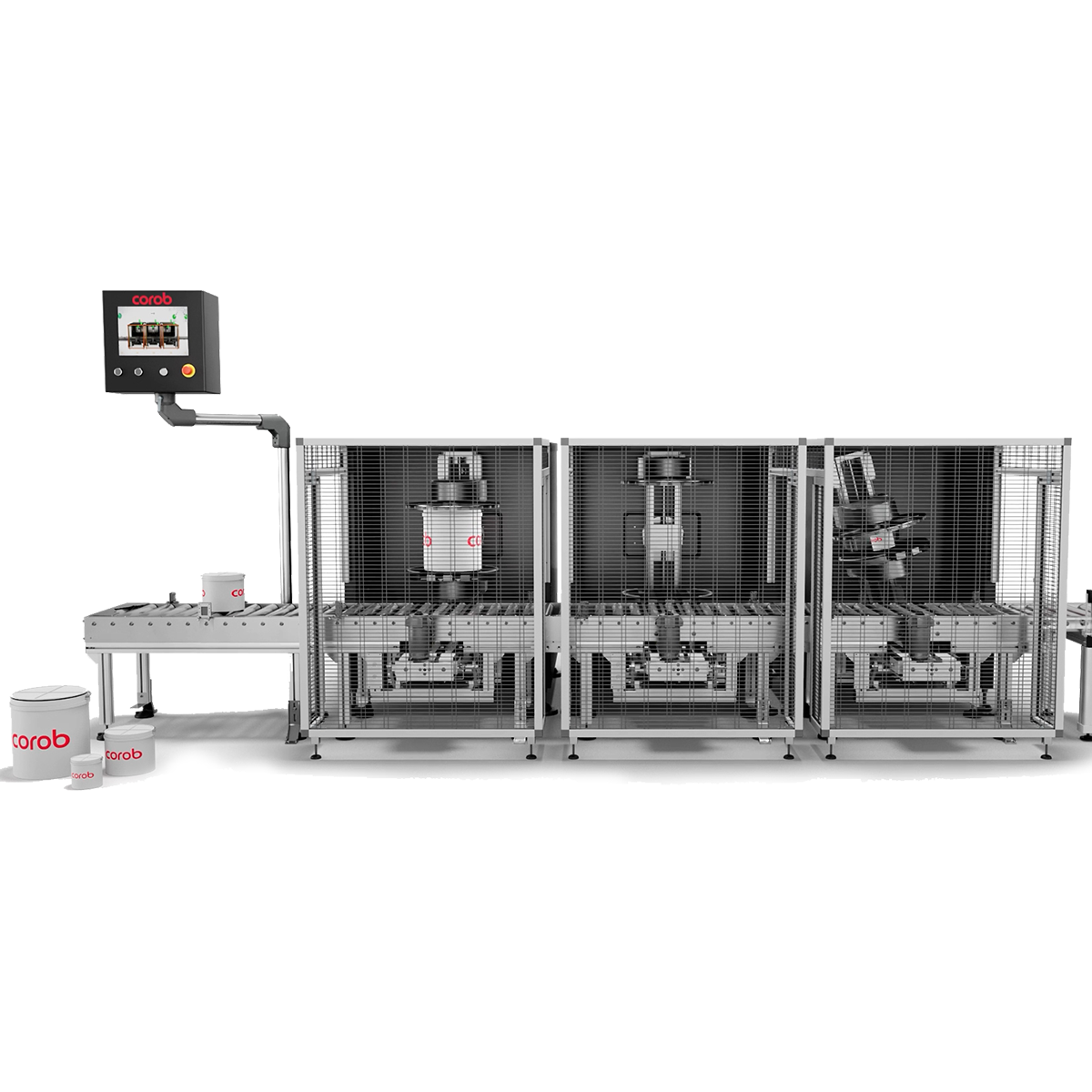

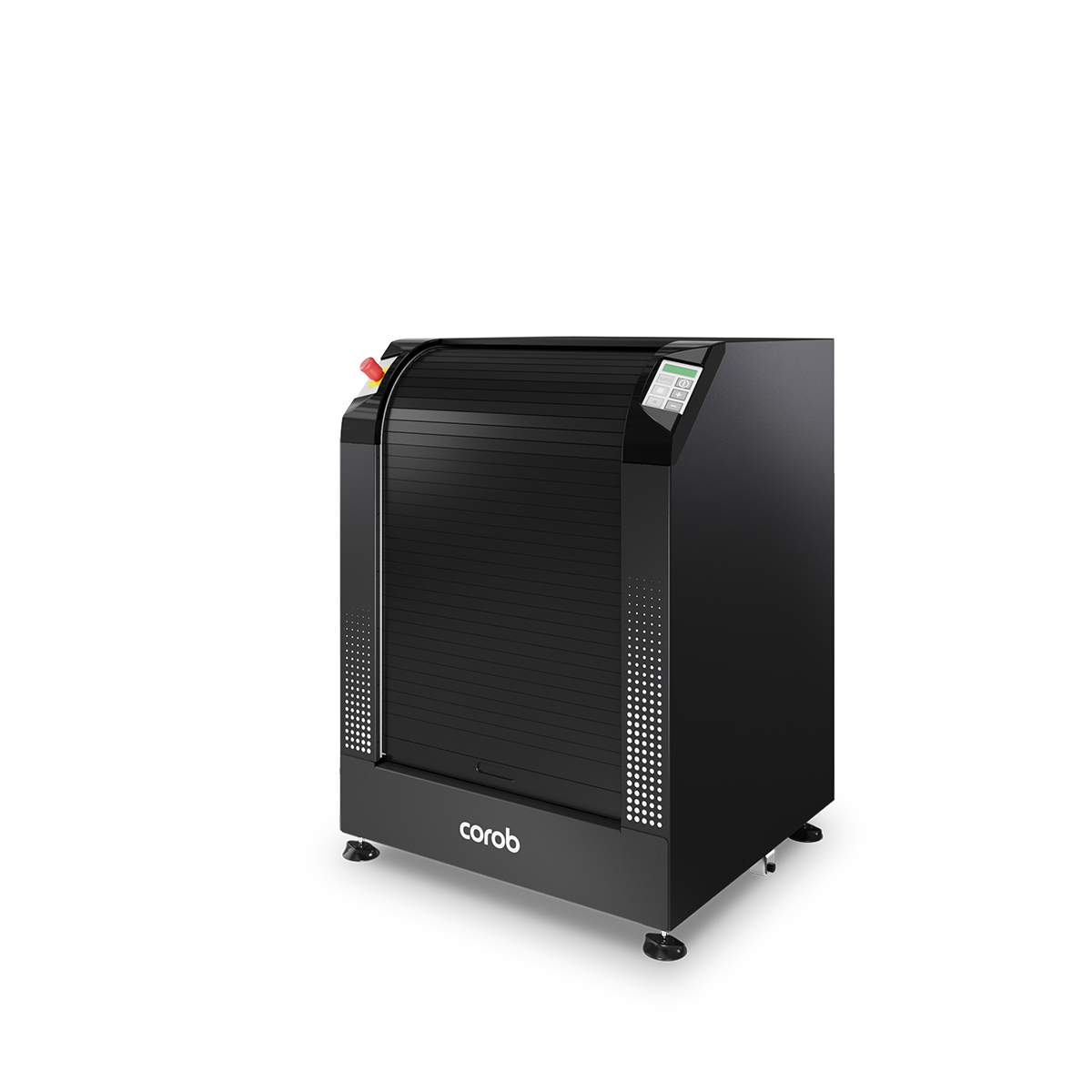

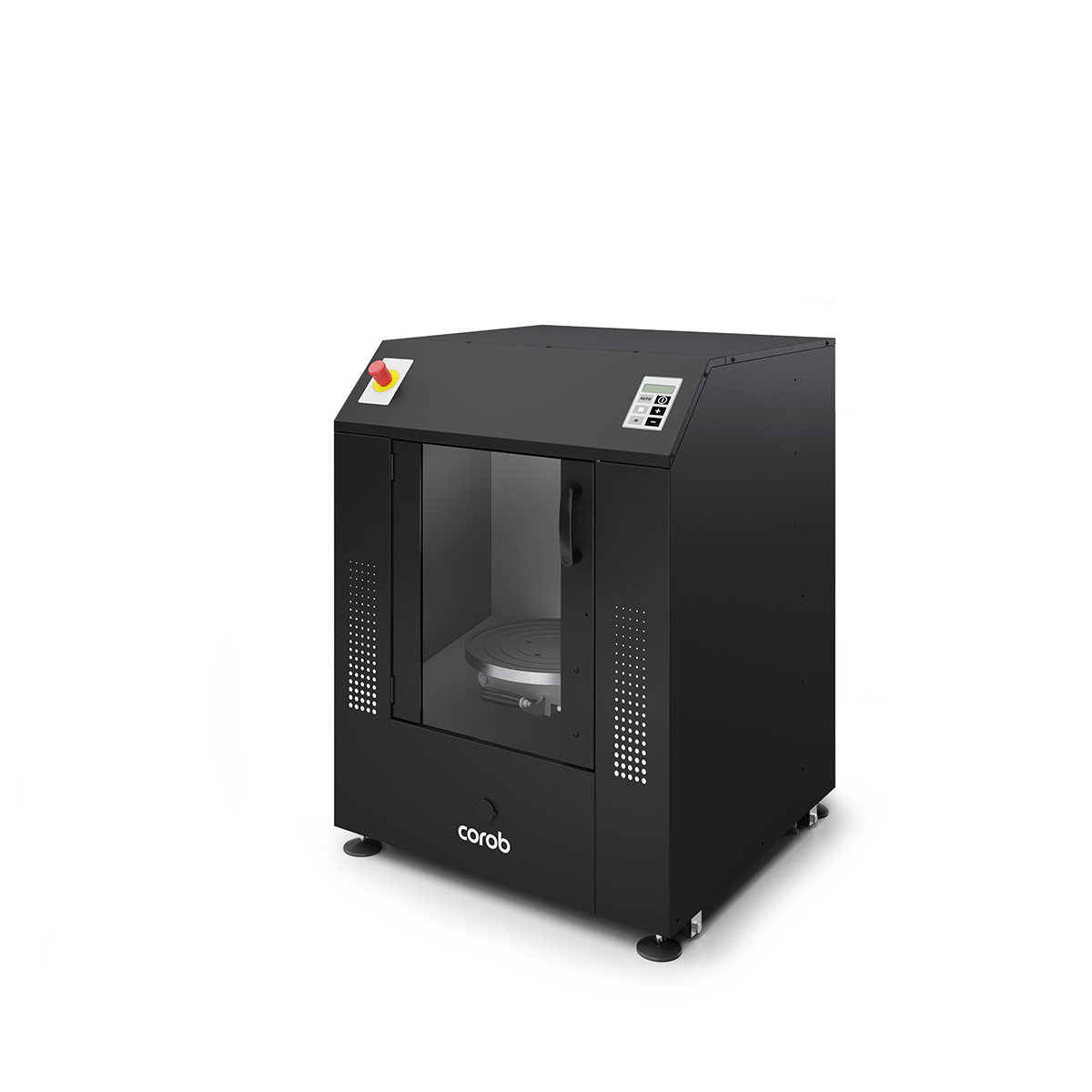

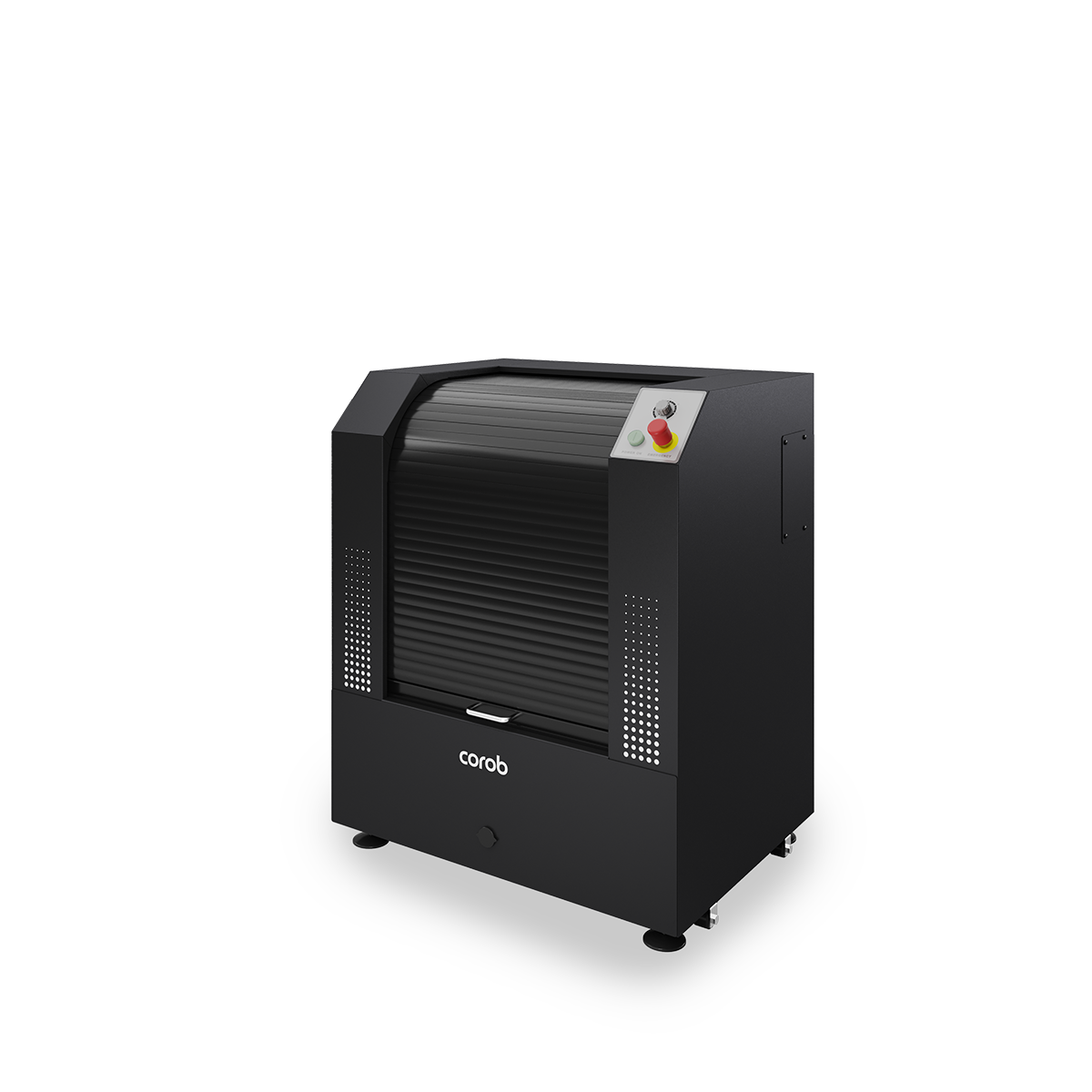

COROB technology integrates seamlessly with organic materials such as leather and other natural substrates, offering advanced dispensing and dosing solutions tailored to the specific needs of the leather industry.

Leather processing often involves highly variable substrates, requiring systems that are:

COROB’s expertise in dosing complex mixtures allows for precise formulation of tanning agents, dyes, and finishing chemicals.

With scalable configurations and customizable layouts, COROB solutions help leather manufacturers optimize production, reduce costs, and meet evolving market demands with confidence.

Our systems support:

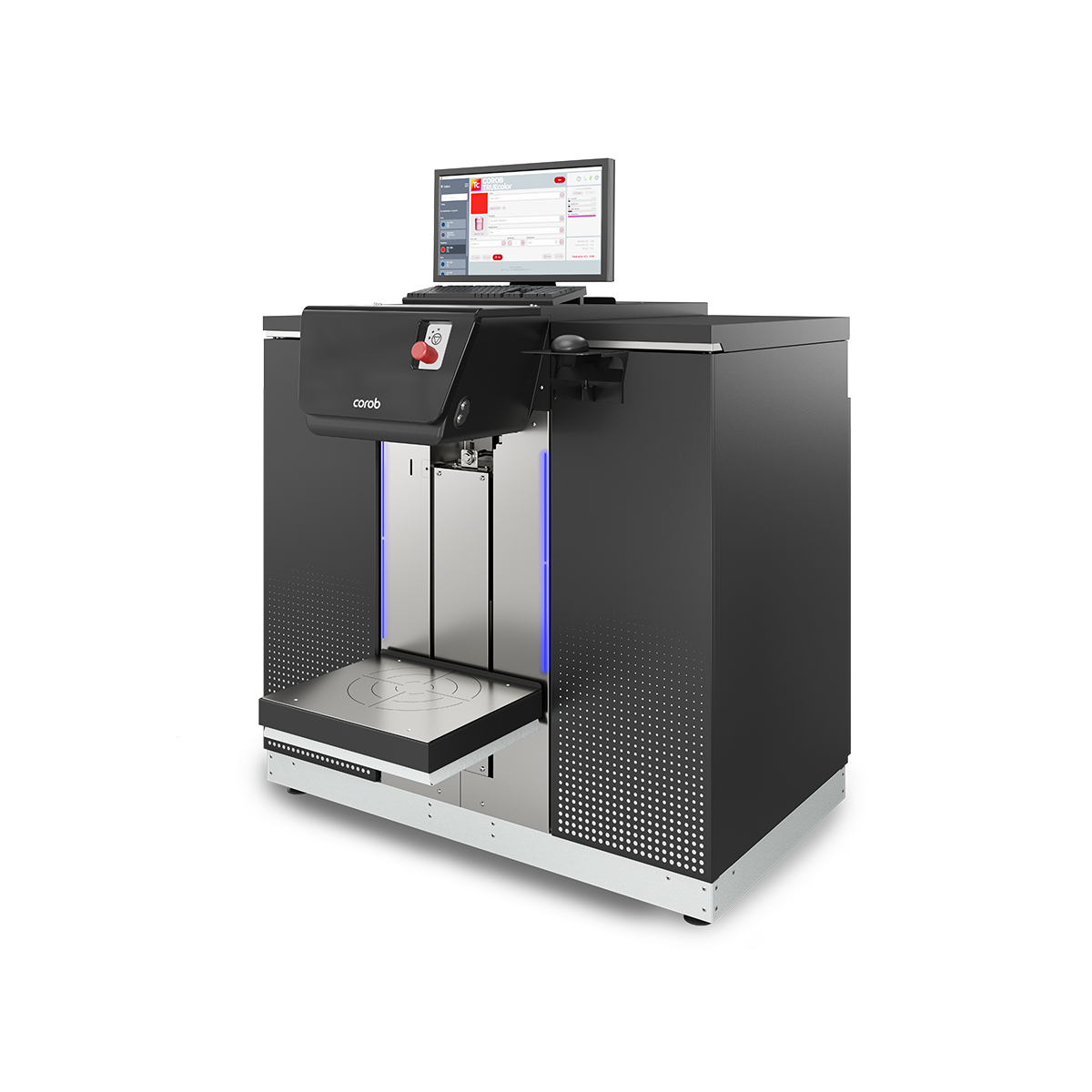

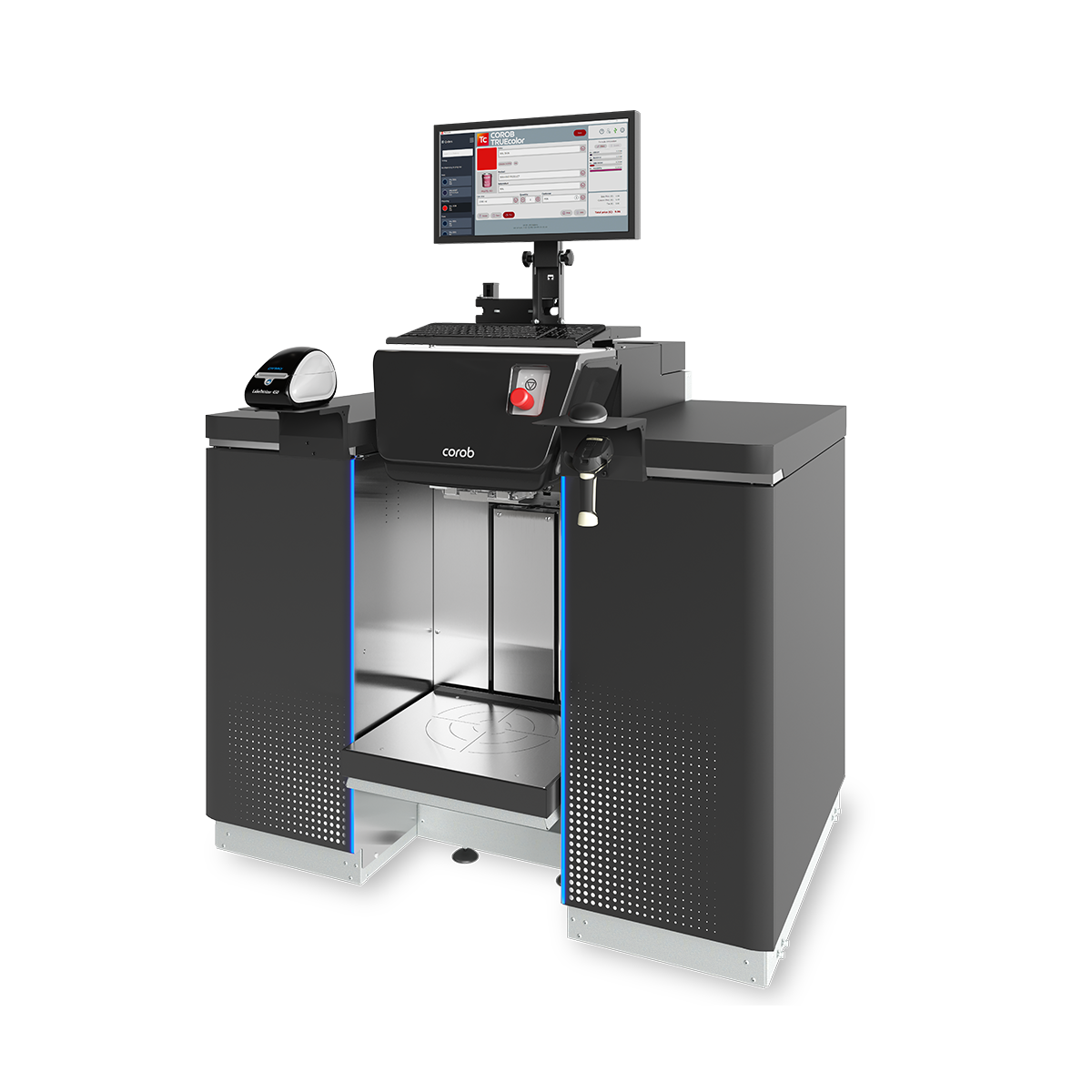

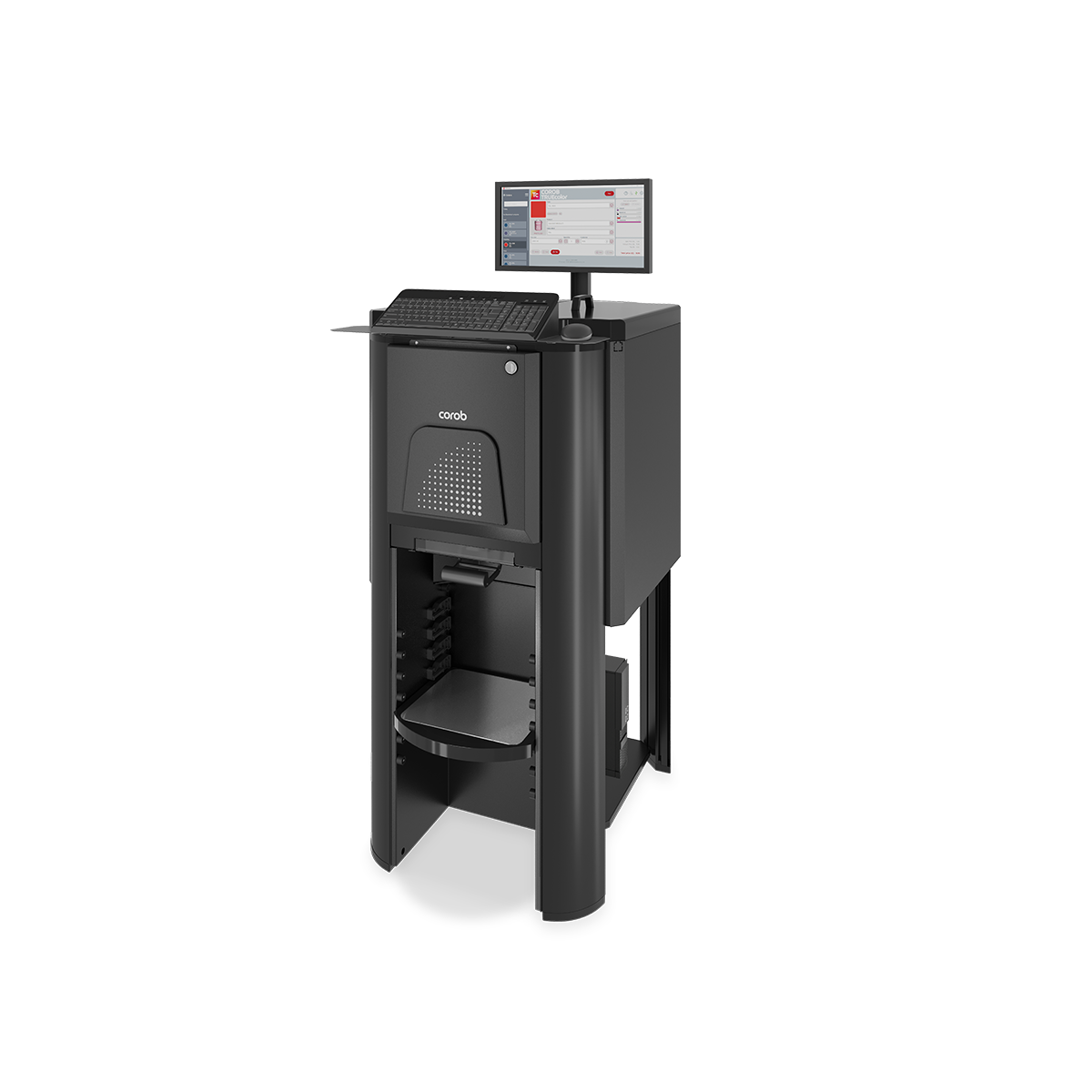

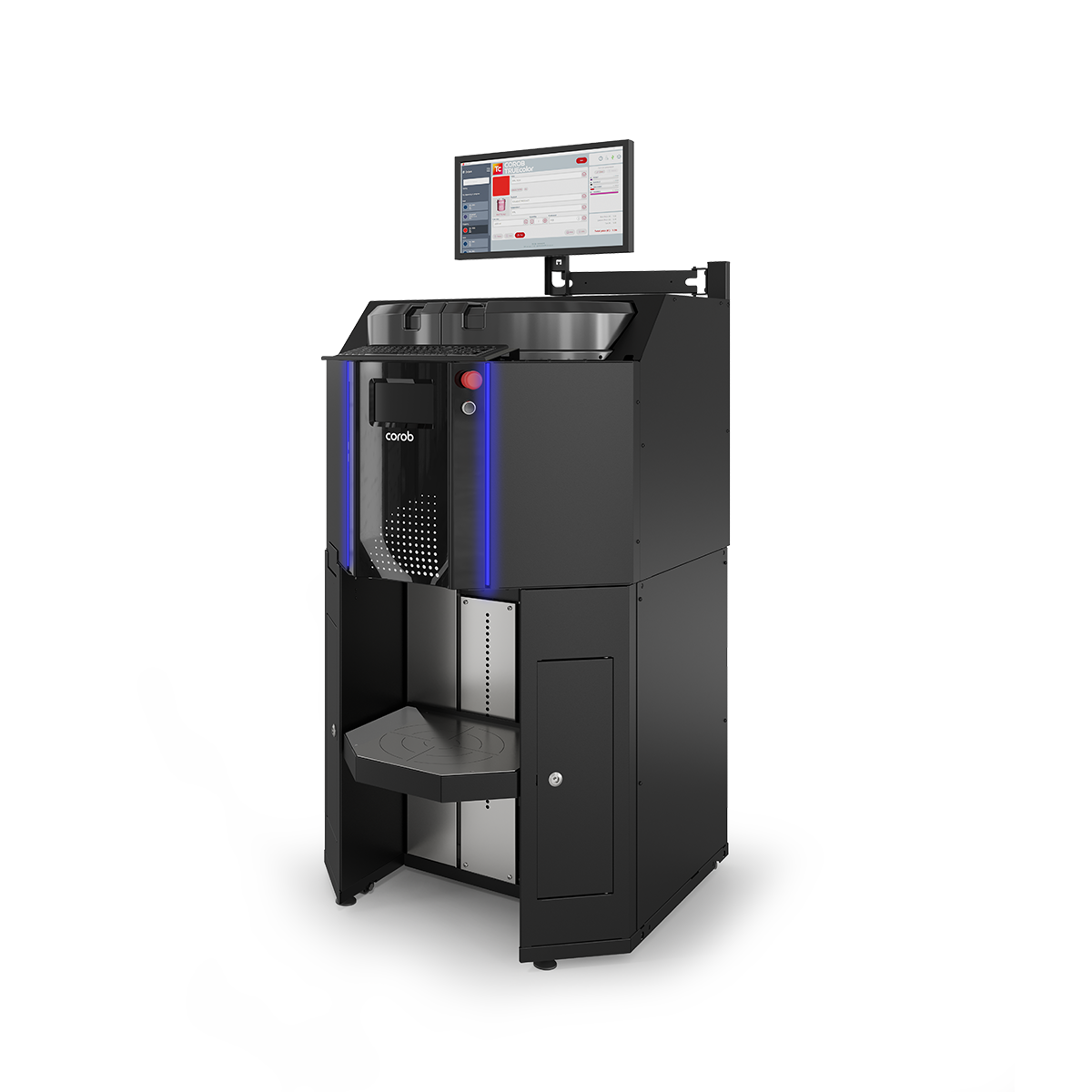

![T200 [S] Turntable dispenser piston small](https://www.corob.com/wp-content/uploads/2025/12/T200-S-Turntable-dispenser-piston-small.png)