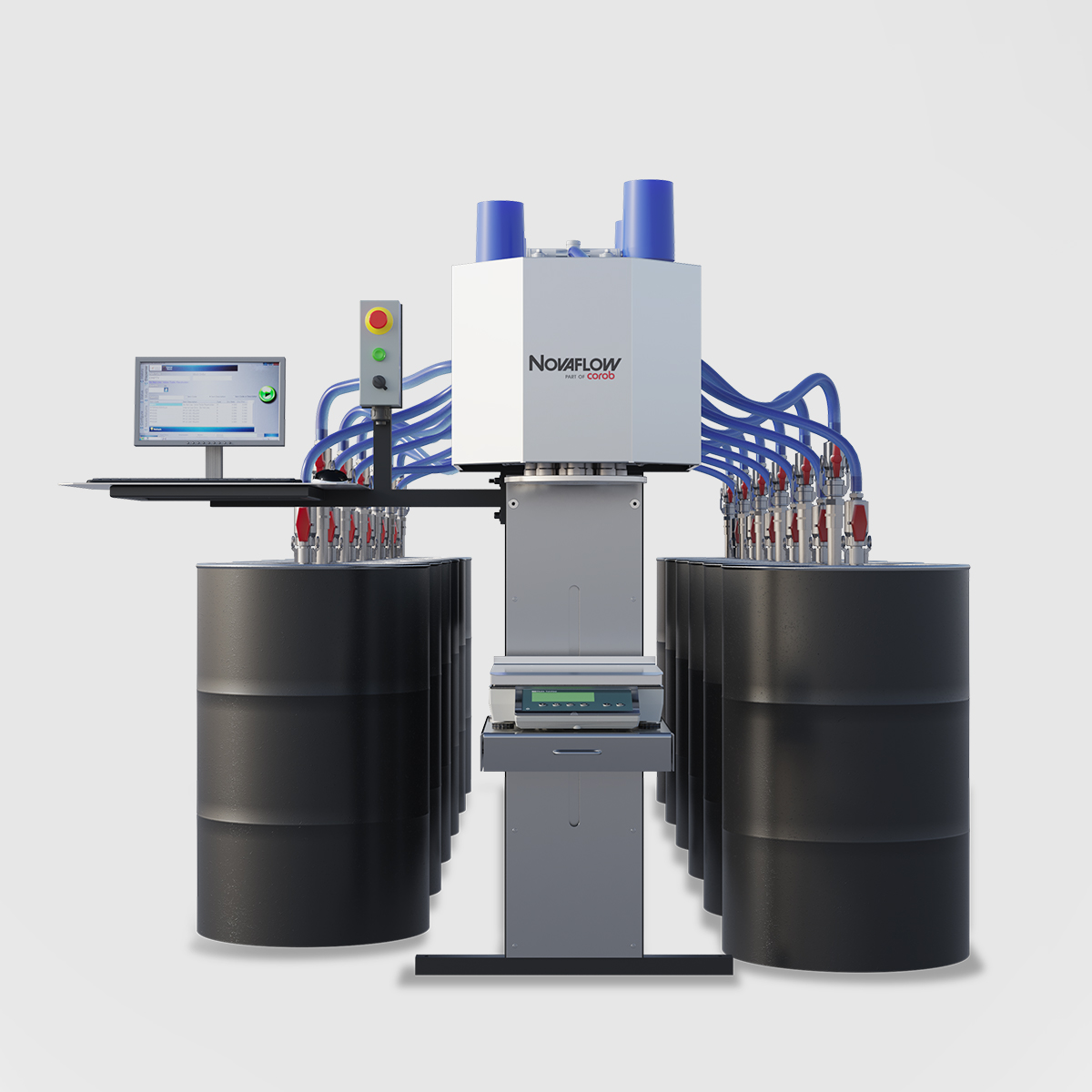

Designed specifically for small batch production environments, the N20W is a weight-based dispenser ideal when producing water, oil or UV-based products.

The N20W is a cost-effective system designed to provide fully automated dispensing benefits without major capital outlay. The system is designed for small batching operations producing from 1 to 5-gallon batch sizes.

A fully functioning unit installs in only a few hours. The N20W uses two-stage stainless steel valves. This unique valve technology optimizes dispense speed and dispense accuracy, offering unparalleled accuracy batch after batch.

Materials can be pumped from buckets, drums, or bulk containers.