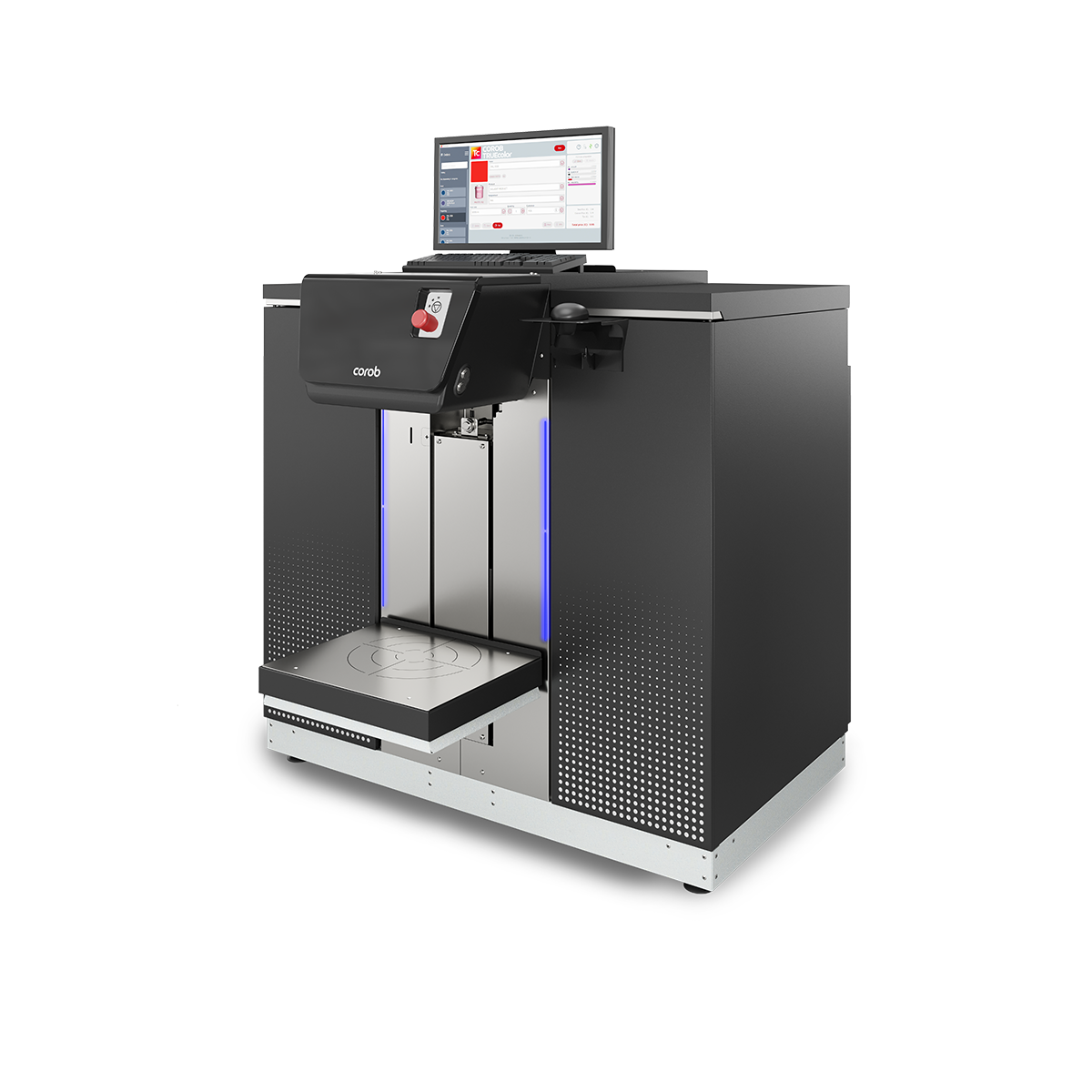

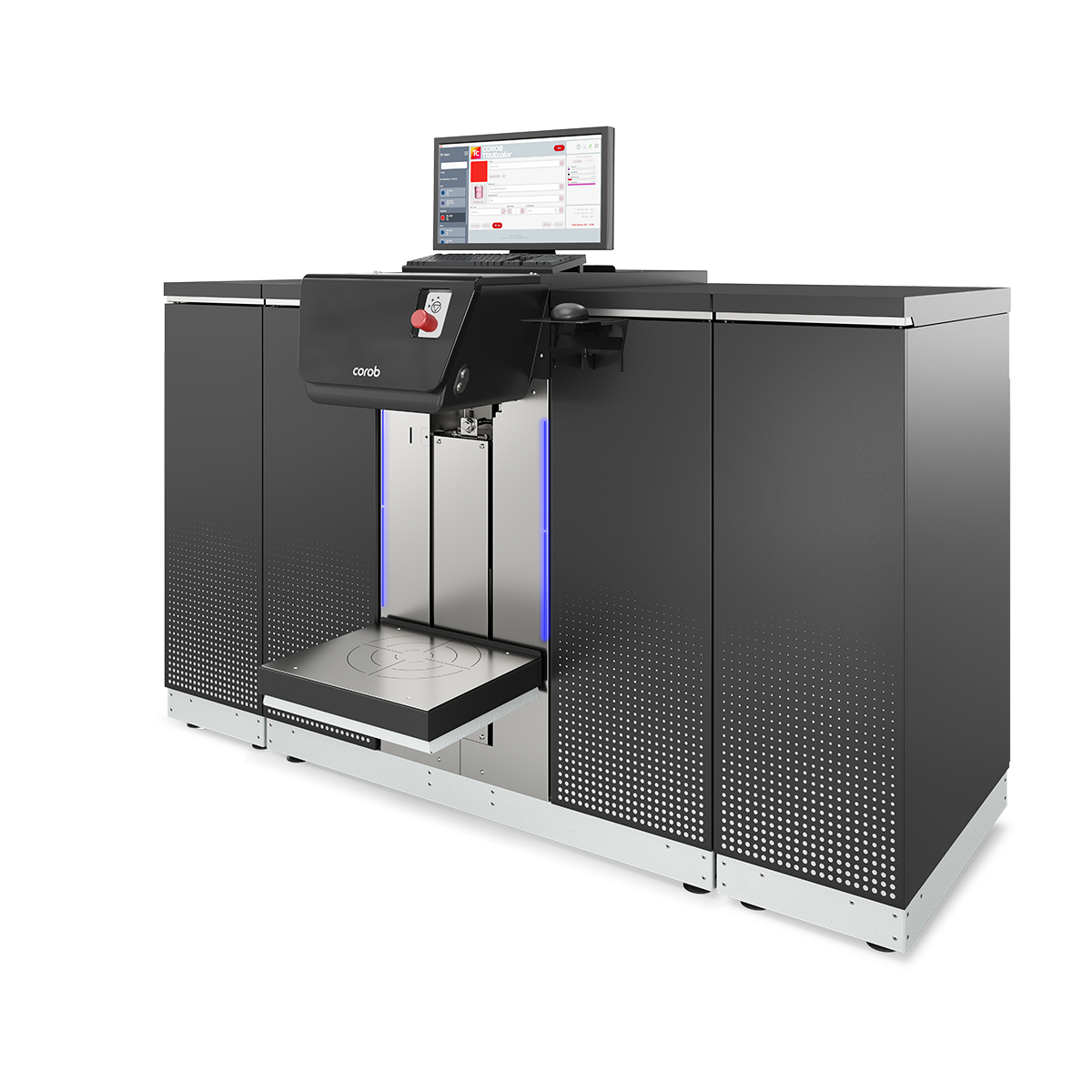

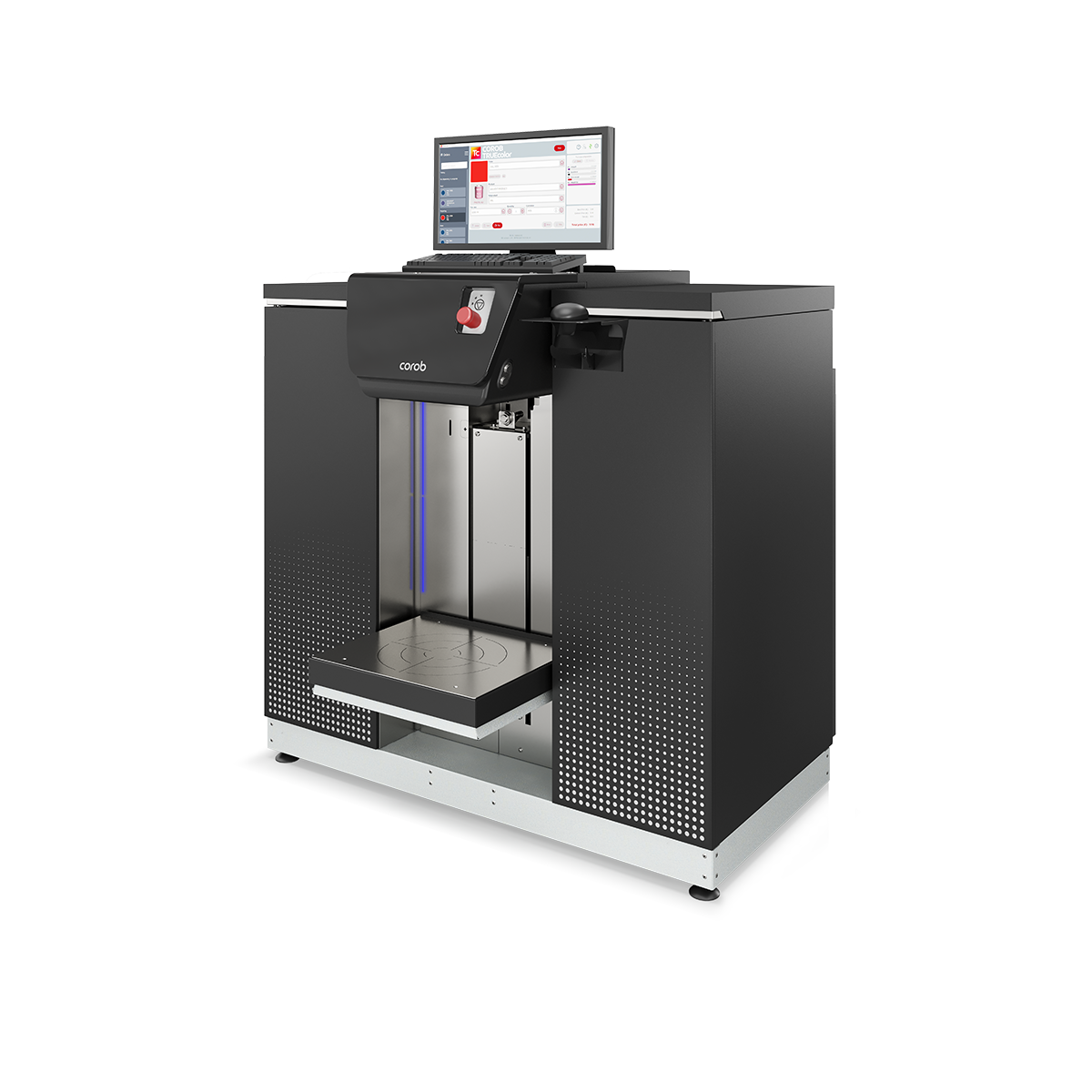

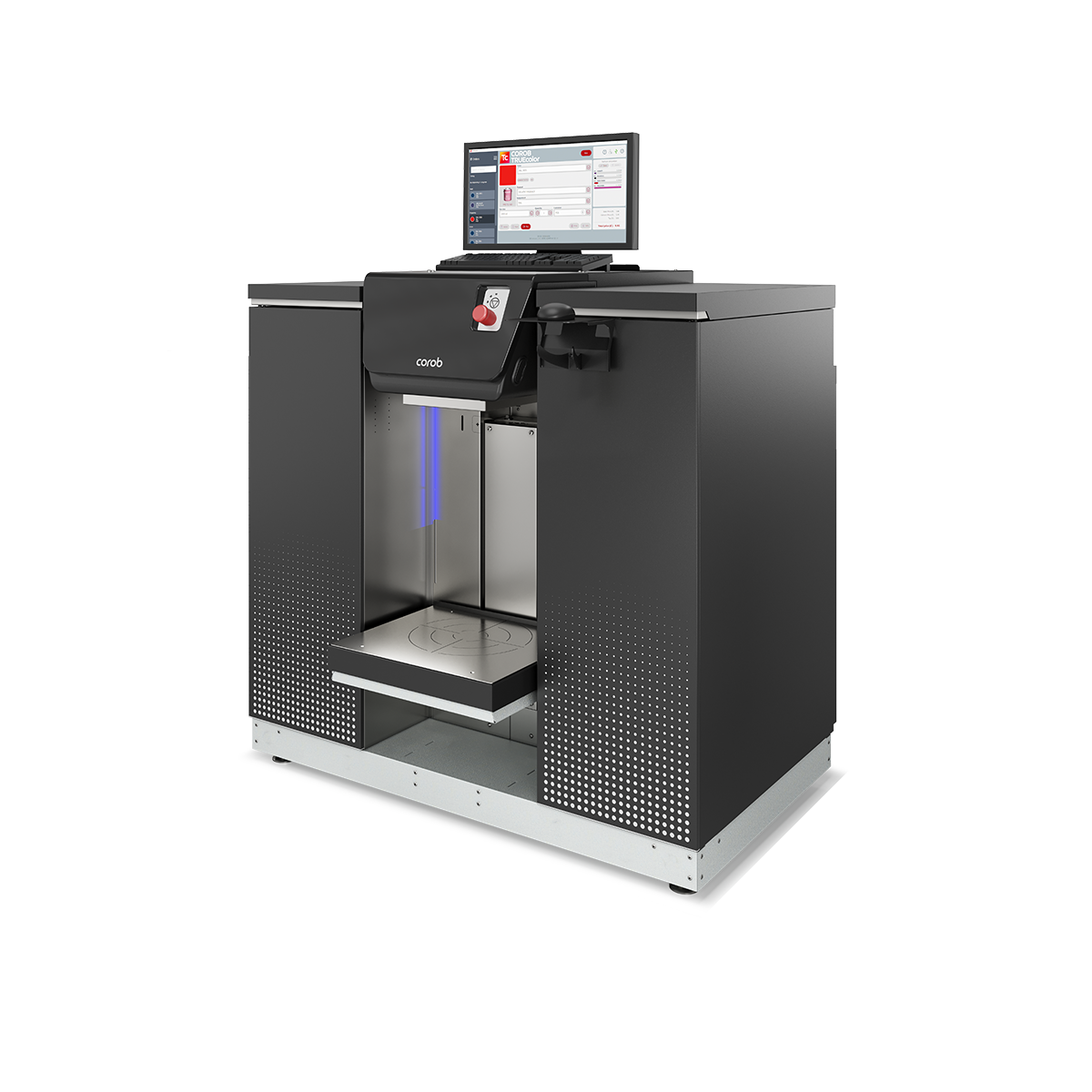

Our most advanced automatic paint dispenser, the EVOPWR delivers exceptional performance in terms of quality, accuracy and speed. It is the ideal tool for distribution centers and professional paint stores where productivity and reliability are critical factors.

With its ability to dispense up to 8 liters of colorant per minute, the COROB EVOPWR is a fast simultaneous dispenser with the flexibility to be configured to meet your exact business needs.

For the ultimate solution the EVOPWR can be configured with single drive gear pumps or bellows in various combinations to suit your exact productivity requirements. For challenging colorants, individual parameters for dispensing, stirring and recirculation can be selected to maintain the optimal conditions and as the pumps are only driven when needed, this maximizes the reliability, reduces the TCO and lowers power consumption by 50%.

For less demanding situations the EVOPWR can still be configured with the ever popular Central Drive gear pump technology which provides the highest levels of productivity and accuracy COROB is renowned for.

The optional NoPurge INV system is the patented breakthrough dispensing nozzle with 100% re-circulation function and sealed nozzles. It prevents mistints by ensuring colorants do not dry out, saving you time, money and helping the environment by not creating purge waste.

The EVOPWR offers exceptional customization due to its versatile range of canister sizes and layouts and can host up to 32 colorants with an optimized footprint for any configuration. It features a semi or fully automatic shelf and the roll conveyor system for effortless handling of paint cans in any size.